PDS

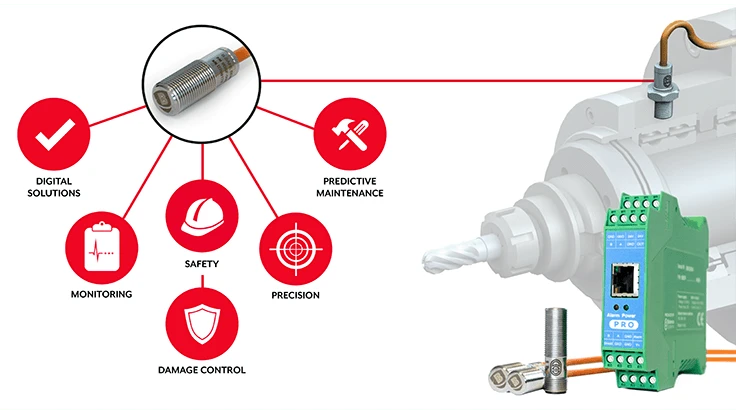

“Precision Drive Systems’ (PDS) Predictive Spindle Maintenance Program is ideal for customers that submit metalworking spindles for repair. The technology to monitor key production metrics can be integrated by our expert technicians,” says Allen Turk, president and CEO of PDS. “Our predictive maintenance services maximize machine uptime and part quality by detecting major spindle problems before costly and time-consuming catastrophic spindle failure.”

PDS Spindle Monitoring technology also protects the machine and workpiece by rapidly shutting down the machine tool in the event of a crash.

During routine spindle repairs performed in PDS’ North Carolina service facility, PDS technicians embed sensors that connect the spindles to the Internet of Things (IoT) employing Industry 4.0 protocols that provide distributive data for manufacturing process improvements. These embedded sensors are hardwired to the machine for real-time, online monitoring of excessive spindle-bearing vibrations and heat to reliably predict the life of the spindle and protect the machine in the event of a crash. This constant monitoring detects major spindle problems before costly and time-consuming catastrophic spindle failure — repairing a seized-up or crashed spindle can cost up to twice as much as repairing a worn spindle that is still running. This predictive spindle maintenance service enables customers to know when to replace tools or adjust speeds and feeds to optimize cutting efficiency, increase productivity and prolong machine life.

PDS also offers a quarterly service where PDS technicians visit the customer’s shop and attach portable wireless sensors to the machine for a quick glimpse at the spindle’s health. This evaluation is then compared to the spindle’s nominal threshold measurements or to PDS’ extensive library of spindle data that can effectively predict spindle life. This quarterly service increases productivity by eliminating scrap and wasteful, excessive machine downtime before the spindle catastrophically fails.

Latest from Today's Medical Developments

- German robotics and automation in a downturn

- Blueshift’s AeroZero

- November USMTO grow from October

- Platinum Tooling’s custom and special tooling

- Top 5 global robotics trends 2025

- Accumold’s micro molding innovations

- Methods Machine Tools, Multiaxis, announce AI solution investment

- MGS to showcase global expansion and healthcare CDMO expertise