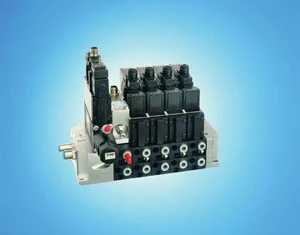

Rexroth has developed a pneumatic modular system to monitor part presence that fulfills the strictest user demands in terms of technology, user-friendliness, and size.

The new compact system controls the presence, position, shape, and dimensions of test objects. The object is scanned using an air-jet from a sensor nozzle. Simultaneous evaluation of the previously defined pressure sends an output to the user in the form of electrical signals. These signals are processed by the machine control system and displayed on the module.The control system either releases the workpiece for processing or stops the process. This contributes to improving the quality of the test object, but it also avoids errors. The block solution with the proven CD01 valve system can be integrated into any machine control system and up to 6 test modules can be combined in the system solution. In addition to this, the technical design of the system makes it insensitive to primary pressure fluctuations. Pneumatic part present sensing from Rexroth has precise measuring accuracy of up to 0.01 mm. The MS01 is also equipped with an integrated air blowing function to prevent the measured results from being incorrectly influenced by contaminants such as shavings or coolant. As a result, regular surface cleaning is guaranteed with this function. The air blowing function can be regulated to keep compressed air consumption to a minimum, making the MS01 more efficient than most other pneumatic systems. A combination of optical and mechanical system components also allows individuals to quickly and easily set the correct gap limit between the workpiece and the sensor nozzle.

Bosch Rexroth Corp. Hoffman Estates, IL boschrexroth-us.com Booth #D-4320

Explore the July August 2006 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Kistler offers service for piezoelectric force sensors and measuring chains

- Creaform’s Pro version of Scan-to-CAD Application Module

- Humanoid robots to become the next US-China battleground

- Air Turbine Technology’s Air Turbine Spindles 601 Series

- Copper nanoparticles could reduce infection risk of implanted medical device

- Renishaw's TEMPUS technology, RenAM 500 metal AM system

- #52 - Manufacturing Matters - Fall 2024 Aerospace Industry Outlook with Richard Aboulafia

- Tariffs threaten small business growth, increase costs across industries