The metals and medical industries are inextricably linked, with improvements in metal supply and the development of new alloys driving the safe use of internal and external medical devices.

Titanium medical devices

In its pure form, titanium exhibits low-density, high-strength characteristics, and corrosion resistance crucial for medical applications. Certain titanium alloys (particularly Ti-6Al-4V and Ti-6Al-4V ELI) are non-reactive with bodily fluids, negating the risk of implant rejection, and when properly treated, bond well with human bone for extremely secure fixation.

Due to its resistance to body fluids, strength, and low modulus, common medical uses of titanium are orthopedic devices such as hip, spinal, facial, shoulder, elbow, and knee replacements. In addition, some heart valves use titanium housings, and surgeons use titanium pegs to attach prosthetic eyes and ears. It is also the standard shield material for pacemakers and defibrillator cases.

Titanium is suitable for surgical instruments such as drills, forceps, retractors, scissors, needle holders, and eye surgery equipment. The non-ferromagnetic metal is also compatible with MRIs or CT scans.

Titanium manufacturing

The key limiting characteristic of titanium is its cost, which is significantly higher than aluminum and steel alloys. Inherently difficult to extract from its ores, titanium is also costly because carbon cannot be used as the reducing agent as it produces a carbide when heated with the material. Instead, pricier reducing agents such as sodium and magnesium have to be used to ensure production of the pure metal.

Once alloyed, titanium can be 10x to 100x slower to machine than aluminum alloys. Cost implications, therefore, demand that any manufacturing technology minimizes waste.

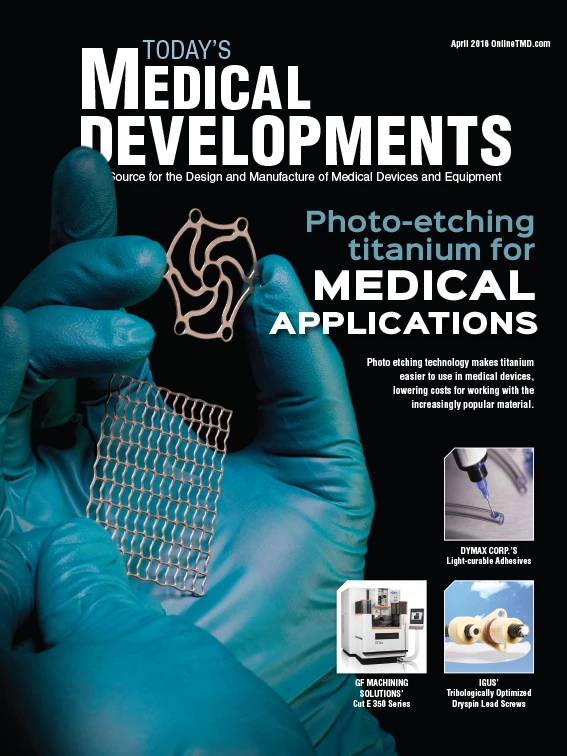

Recent developments of photo etching at Precision Micro Ltd. found a solution resulting in practical and economical use of titanium in medical applications. For complex parts, or parts where the retention of material properties is important, photo etching is more accurate and cost-effective than many traditional industry alternatives such as stamping, pressing, punching, or laser and water-jet cutting.

Photo etching produces burr-free parts with clean profiles, eliminating heat-affected zones and delivering stress-free parts with unaffected metal properties. As the process relies on digital tooling, multiple design iterations can be quickly and inexpensively produced with no effect on time-to-market.

The process is fast and economical with lead times in days not weeks, and is precise down to micro levels, accuracy even on the most complex of parts being a key attribute. It is also highly repeatable and economical, with an image of the parts to be manufactured effectively being printed on the sheet metal, and all of the parts etched at the same time. The digital photo tooling used to print the image of the parts ensures that parts produced now are identical to parts produced a decade later.

Getting results

Photo etching opens up a new route to medical part production with many inherent advantages that can be applied to the serial manufacture of titanium parts. While the cost of design iterations are dramatically reduced using this process, engaging a partner early in the development stage of the product life cycle ensures design for manufacturability, maximum cost efficiency, and the most success with photo etching results.

Precision Micro

About the author: Albert Tsang, technical manager at Precision Micro, Birmingham, UK, can be reached at 44.0.121.380.0100 or info@precisionmicro.com.

Explore the April 2016 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Teleflex sells acute care and urology businesses for $2.03 billion

- HANNOVER MESSE: Where research and manufacturing meet

- What’s next for the design and manufacturing industry in 2026?

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Robot orders accelerate in Q3