Nurses face the daily challenge of caring for an overweight population, which can often lead to debilitating injuries.

PowerNurse, a motorized lateral transfer device, enables even the smallest nurse to move a heavy patient.

One of the growing problems facing the nursing career is a thinning staff, and with it the need to care for overweight patients with very little help. This effort has led to musculoskeletal disorders (MSDs) including back injuries, the most costly MSD injury. In fact, 12% of nurses leave the profession each year due to back injuries, and 52% suffer from chronic back pain. Those working in nursing homes have an even higher rate of injuries. Until recently, moving a patient was performed manually or with minimal automation.

Allowing a single nurse to safely and comfortably transfer a patient without risk of injury required a fully-automated device. Astir Technologies took this on as a goal, to use the latest technologies available to provide patient transfer in a manner that decreases hospital costs and reduces injuries to health care professionals while minimizing discomfort to the patient. With this in mind, the company designed and manufactured the PowerNurse.

All of the mechanisms are packaged in a low-profile (74" x 28" x 2.3") assembly that rides over a standard hospital stretcher. With the PowerNurse, patients can be moved between hospital beds, stretchers, imaging equipment, operating room tables and exam tables. According to Chris McNulty, Astir Technologies president and developer of the PowerNurse, "Other less expensive, friction-reducing devices decrease but do not eliminate the risk of nurse injury while performing a lateral transfer." As with other advanced designs, the PowerNurse was made possible with the advances to technologies and the miniaturization that has taken place in recent years. A critical area evident in the device's design is that of the motors and gearboxes. High power rare earth magnets and advances in motor winding have resulted in high torque motors in small packages.

"Maxon leads the industry with a wide selection of high end products that made it possible to lower the profile of the PowerNurse, leading to a more comfortable and effective product," McNulty says.

|

|

PowerNurse transfers a patient from one

hospital bed to another by simultaneously

crawling under the patient while at the

same time moving the patient on top. | |

McNulty's solution involves a series of conveyor belts, motors and electronics that fit into a thin profile, allowing the automatic transfer of very heavy weights. During development of his first prototype, over 400 lb was easily transferred using one-fifth of the capacity of the 250W Maxon EC45 motors designed into the device. This meant that the 120W ECmax 40 motors could be used in the PowerNurse, while the larger EC45 motors could be used for a bariatric model in development.

Originally, the PowerNurse traveled at only one speed (1ips). Although this speed was fine for patient pick-up and delivery, it was too slow for the lateral transfer process. So, McNulty incorporated a two-speed option into his beta model, where the device operated at 1ips or 2ips. "Maxon's wide selection of gearbox diameters, gear ratios, and number of gear stages, allowed us to fine tune the products overall speed while maintaining the highest level of torque," McNulty explains.

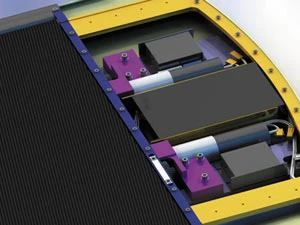

Paring the Maxon DEC 50/5 motor control with either the EC45 or ECmax 40 motor smoothed the design as well as the overall operation of the device. The PowerNurse incorporates four ECmax 40 motors; four GP 42C, three-stage, 43:1 gearboxes; and four DEC50/5 servo-amplifiers along with a 400W, 48VDC power supply.

A specific challenge i n the development of the device concerned the drive rollers, which undergo tremendous torque delivered by the Maxon gearbox geared down even further through a 2:1 reduction to the drive shaft. This situation resulted in a lengthy process of evaluating knurled rollers, smooth rollers and polyurethane coated rollers. In the end, the coated rollers delivered the response desired and handled the torque levels delivered by the motors very well.

An all push-button-driven device, PowerNurse requires no software interface and operates in three distinct modes: burrow, pad align and transfer.

During the burrow mode, belts are used to pull the patient onto the top of the device while belts on the bottom move the device under the patient. Done simultaneously, the result is the patient feels a much smoother transfer than with many other devices.

Four Maxon DEC 50/5 servo amplifiers are designed into the PowerNurse to provide easy control of the motion of the device

In pad align mode only the top conveyor belts are energized. This aligns the patient and incontinence pad if necessary.

Transfer mode energizes only the bottom belts, which transfers the PowerNurse, with the patient riding on top of the device, to an adjacent surface.

Rotation and translation are available in any mode and the result is a tanklike translation or rotation. Four Maxon motors are required to achieve all of the device's operational modes.

Astir Technologies is now investigating the addition of a yaw gyro for the system, to enhance the machine-human interface and bring the motor controls to a new level of performance. This is expected to make the PowerNurse even easier to use.

Maxon Precision Motors Inc.

Fall River, MA

maxonmotorusa.com

Astir Technologies

Concord, MA

astirtechnologies.com

Explore the May 2009 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Robot orders accelerate in Q3

- Pro Shrink TubeChiller makes shrink-fit tool holding safer, easier

- Revolutionizing biocompatibility: The role of amnion in next-generation medical devices

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.