Delcam CRISPIN has added options for the creation of anatomical orthotics to its OrthoModel software for the design and manufacture of orthotic insoles.

The updated version also includes a new method to define heel lift; improve arch definition; create greater flexibility when producing unique orthotics from standard models; and enhanced graphics and workflow to make the system even easier to use.

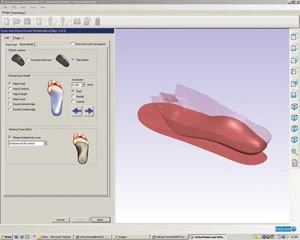

OrthoModel provides a complete solution for the design of high-quality insoles for both comfort and for the medical markets. The entire process is driven by a series of easy-to-use menus that incorporate terminology and imagery familiar to the industry to describe the various features of the orthotic. This makes it easy for medical and footwear professionals to use the software, even those having no previous computer experience.

OrthoModel is completely open and can take data from any scanning system or use manual measurements from a prescription.

The anatomical option allows scan data to be taken from part of the plantar scan or the entire plantar scan, representing the chosen sections of the sole and heel of the foot.

This shape can then be reproduced exactly in the orthotic design to give the optimum contact area between the base of the foot and the device, spreading the weight of the body as widely as required.

Most importantly, a smooth blend can be created between the contact area of the orthotic and the inside of the shoe, ensuring that the foot is correctly matched with the surface of the orthotic while walking.

This is an essential requirement for patients with diabetes, as well as giving improved results for comfort orthotics.

The arch is one of the most critical areas within the foot. If it does not flatten sufficiently, it absorbs shock poorly, putting extra stress on the foot, especially on the heel.

Alternatively, if the arch flattens too much, the foot will be unstable and the bones can become misaligned.

Improved definition in this area within OrthoModel will give a more effective and comfortable orthotic.

Many orthotics are purely accommodative so they do not require such high levels of customization.

In these cases, the designs are often created from a range of base models that can be adapted with add-ons or cut-outs for the individual patient. This approach has been further supported in the new release with an expanded library of components, plus the ability for the user to add their own shapes to this library.

In addition, it is possible for the design of these styles to be batched, allowing the operator to input prescriptions for a number of patients together with the associated base model for each case. The software can then generate all the required designs in a continuous series of calculations, carrying the process out overnight, giving maximum productivity to the designer.

Explore the October 2009 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- November USMTO grow from October

- Platinum Tooling’s custom and special tooling

- Top 5 global robotics trends 2025

- Accumold’s micro molding innovations

- Methods Machine Tools, Multiaxis, announce AI solution investment

- MGS to showcase global expansion and healthcare CDMO expertise

- Medtronic: 5 healthcare tech trends for 2025

- Norman Noble launches enhanced laser welding capabilities; expands micromachining in Florida