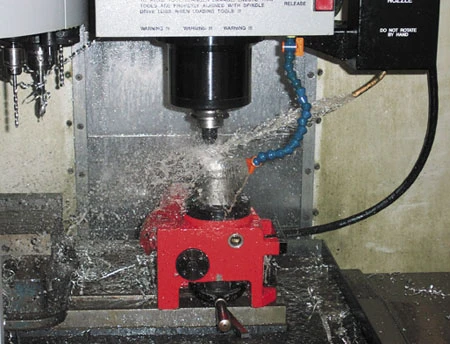

Shop finds metalworking fluid for all its operations.

P rototype and production-machining job shop TNS Machining in Muskego, Wis., works with a variety of materials and machining operations. Thus, it was constantly searching for one coolant that would work in all machines requiring water-soluble fluids. The solution was Picocool 5254, a high-tech synthetic coolant that works in various operations, maintains performance with local water conditions, and keeps sumps and delivery systems bacteria free.

"From the first day and after many months," says Scott Rowinski, vice president of TNS, "the coolant has met every objective as our one universal and versatile shop-wide product for water-soluble systems."

TNS has experienced all coolant problems, including Monday-morning stink, tacky and oily residues, rusty parts, dermatitis, tramp-oil contamination, inadequate lubrication, short sump life, and excessive foaming and bacterial growth. These problems were often uncontrollable as machining jobs changed and CNC sumps remained shut down for several days. In addition, machining problems caused by coolant variations degraded operations such as aluminum threading and grinding.

Picocool 5254's clear solution lets TNS workers inspect work and tooling and leaves machinery and parts clean. All tramp oils quickly split out from the coolant and easily skim off sumps. During severe machining, there is no oil smoke or heat-generated vapor mist. And using standard hygiene practices, workers handle parts without experiencing skin problems.

Pico Chemical Corp.

Chicago Heights, Ill.

picochemical.com

Circle 204

Explore the July 2005 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- HERMES AWARD 2025 – Jury nominates three tech innovations

- Vision Engineering’s EVO Cam HALO

- How to Reduce First Article Inspection Creation Time by 70% to 90% with DISCUS Software

- FANUC America launches new robot tutorial website for all

- Murata Machinery USA’s MT1065EX twin-spindle, CNC turning center

- #40 - Lunch & Learn with Fagor Automation

- Kistler offers service for piezoelectric force sensors and measuring chains

- Creaform’s Pro version of Scan-to-CAD Application Module