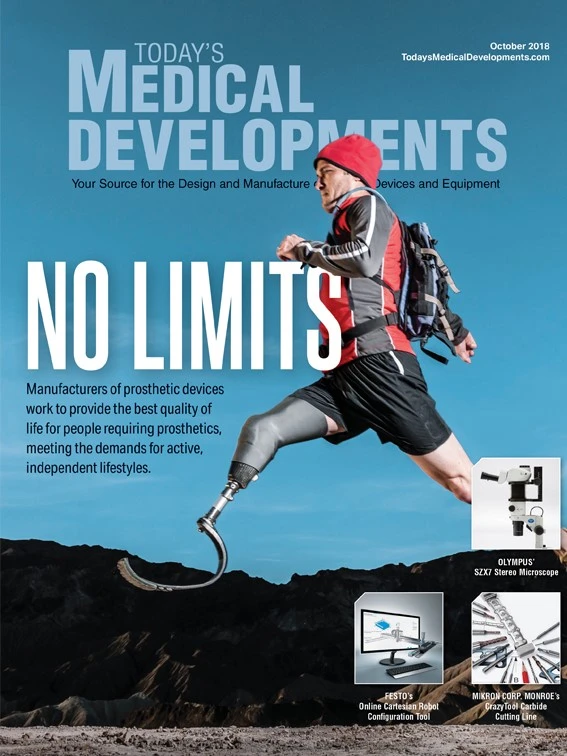

With amputation becoming more common and nearly 200,000 performed annually in the United States, device designers are crafting more-sophisticated prosthetics with a larger number of moving parts.

“Prosthetic performance, especially for complex devices, is improving at a rapid rate, and most prosthetics now incorporate a hydraulic system whereby the user can vary the damping force to help cushion shock loads,” says Jerry Zawada, sales engineer for healthcare and medical at Trelleborg Sealing Solutions. “More advanced systems use a microprocessor with some element of intelligent learning to make adjustments when a prosthetic user is standing, walking, running, or climbing stairs.”

Design challenges

One of the main challenges with advanced knee and ankle devices is robustly sealing hydraulic cylinders.

“The sealing systems for the piston and rod in ankle devices are generally similar to those used in knees,” Zawada says. “However, performance is more difficult to achieve in the ankle because ankles are more compact, have a much shorter stroke, and must allow a degree of rotation. This makes side-loading more problematic.”

The cylinder requires a sealing system for the piston and the rod. Designers must seal the piston on the outside diameter to maximize the effectiveness of electronic valves, forcing the fluid through the piston valve in a controlled manner. Seal materials must be compatible with the lubricating fluid to ensure a long life for the prosthetic in various temperatures.

For most devices, engineers strive for a zero-leakage system, which can be difficult. Also, bleed-down can occur during prolonged inactivity, such as when the prosthetic is sitting idle overnight.

In this case, oil stuck on the piston slides down, creating a pool of oil on top of the outer seal. In addition, designers must balance seal and lip load to seal in the hydraulic fluid without creating excess rod friction.

To avoid stick-slip, which can cause an impact shock to the prosthetic user, manufacturers should use low-friction materials. Adding a wear ring or two on the piston keeps the piston aligned properly during side loading. The seal and bearing materials must be compatible with the cylinder-bore material, surface finish, and coatings to maximize cycle life.

The rod sealing system serves two distinct functions: preventing external contamination from entering the system, and keeping hydraulic fluids inside the cylinder. A complex configuration of multiple seals achieves both goals, with each seal performing a separate function to guarantee optimum performance in combination.

Next steps

“Every year there seems to be no limit to the technological advancements when it comes to new prosthetic designs and the sealing solutions behind them,” Zawada says.

Futuristic versions of advanced prosthetics that have been seen in popular movies in recent decades are already a reality.

“Electronic actuators as part of exoskeletons are helping to rehabilitate patients with limited mobility, due to a stroke, for example, enabling them to move,” Zawada notes. “Progress is also being made with bionic systems where limbs are connected to the body’s nervous system, allowing a user to control prosthetic movement just as they would their own limbs.”

Trelleborg

http://www.trelleborg.com

Explore the October 2018 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Robot orders accelerate in Q3

- Pro Shrink TubeChiller makes shrink-fit tool holding safer, easier

- Revolutionizing biocompatibility: The role of amnion in next-generation medical devices

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.