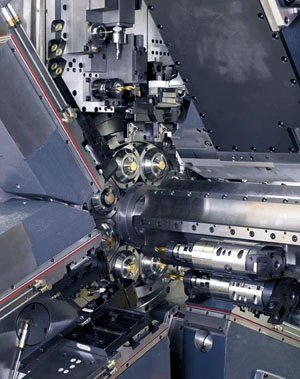

Tornos has developed an eight-spindle machine with two independent, 3-axis back working stations. In operation, positions 1 through 6 are used to perform operations on the front of the part. Every two indexes, two parts are cut off in positions 7 and 8. Those parts are then clutched by the two independent pick off spindles and presented to as many as five tools per part for a variety of back working operations. The new multispindle also features eight independent motorized spindles. Adjustable spindle speeds range from 0 to 8,000 rpm.

The company reports that up to 40 parts per minute can be produced on this machine while maintaining part tolerances of 0.0002 in. Additionally, the MultiDECO 20/8d can be equipped with a palletizer, which is useful for more delicate parts that need to be handled more carefully. With the palletizer, pick and place mechanisms move the part out of the working area and onto a pallet stacked in a wheeled cart for easy transport to a washing or shipping area. As an alternative method, parts may be placed on a conveyor belt featuring part dividers to help avoid nicks and dings. Completing the MultiDECO 20/8d system are the chip and oil management unit and Tornos' dedicated computer-controlled automatic bar feeder that holds up to 80 bars of stock. Standard "live" tool machining attachments permit rotary milling, polygon and thread milling, broaching, and cross-drilling operations.

Tornos Technologies U.S. Corporation Brookfield, CT tornos.com Booth #A-8140

Explore the July August 2006 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Kistler offers service for piezoelectric force sensors and measuring chains

- Creaform’s Pro version of Scan-to-CAD Application Module

- Humanoid robots to become the next US-China battleground

- Air Turbine Technology’s Air Turbine Spindles 601 Series

- Copper nanoparticles could reduce infection risk of implanted medical device

- Renishaw's TEMPUS technology, RenAM 500 metal AM system

- #52 - Manufacturing Matters - Fall 2024 Aerospace Industry Outlook with Richard Aboulafia

- Tariffs threaten small business growth, increase costs across industries