D3 Engineering

Machined for precision linear guidance, Redi-Rail Metric Rails have an aluminum rail with hardened steel races to provide a lightweight design without sacrificing strength. Counter-bore mounting holes allow quick installation in multiple orientations. They can be optimized for corrosion resistance with 440 stainless steel races and used for automated vending, robotic dispensing, large format door-frames, industrial linear guidance, and material handling.

Outfitted with side pre-load adjustment, the metric carriage can be quickly fine-tuned for optimum fit. Sealed rollers allow the carriages to withstand industrial, machine tool, and other tough environments. The anodized aluminum alloy carriage body has tapped mounting holes and sealed, lubricated, double-row ball bearings. A wiper seal maintains operation in tough surroundings. Using a Gothic arch roller design, the carriage glides over particulates for repeatable transfer.

PBC Linear

https://www.pbclinear.com

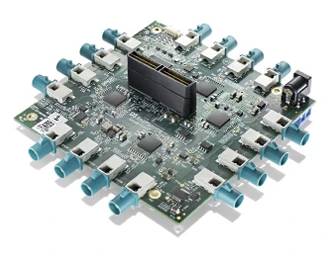

Camera, sensor interface card

The DesignCore sensor interface card allows engineers to quickly connect multiple cameras or sensors with the Nvidia Jetson AGX Xavier Developer Kit to access its full power for system development.

Sensor data is delivered via a serial link and is de-serialized into MIPI CSI-2 data for consumption on the Jetson. This allows the sensors to be placed up to 15m away from the processing unit. GPIO and I2C control are available for configuration and reset. An on-board field-programmable gate array (FPGA) provides hardware-level synchronization capability.

D3 Engineering

https://www.d3engineering.com

United Grinding N. America wins sales growth award

At the 20th annual Fanuc Authorized Systems Integrators (ASI) Meeting, United Grinding North America earned recognition for growing its sales of Fanuc robotic systems. The awards ceremony, in Scottsdale, Arizona, in February 2019, honored distributors and manufacturers who helped customers improve productivity and higher throughput with automated systems.

“We were thrilled to be recognized for our efforts in growing Fanuc sales,” says Simon Bramhall, general manager of United Grinding North America Automation Solutions. “Whether it’s the flexLoad standard automation system or one of the custom solutions we’ve helped develop for customers, we’ve strived to serve as the single-source provider of automated systems for our grinding technology – a mission made possible by our partnership with Fanuc.”

United Grinding

https://www.grinding.com

Explore the May 2019 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- HERMES AWARD 2025 – Jury nominates three tech innovations

- Vision Engineering’s EVO Cam HALO

- How to Reduce First Article Inspection Creation Time by 70% to 90% with DISCUS Software

- FANUC America launches new robot tutorial website for all

- Murata Machinery USA’s MT1065EX twin-spindle, CNC turning center

- #40 - Lunch & Learn with Fagor Automation

- Kistler offers service for piezoelectric force sensors and measuring chains

- Creaform’s Pro version of Scan-to-CAD Application Module