micrometal

micrometal (incorporating HP Etch and Etchform) released a video that focuses on the intricacies and application possibilities of photo-chemical etching (PCE).

The PCE process is used to produce geometrically complex, often feature-rich electronic parts and components for the electronics sector. For electronics OEMs ensuring micron-scale tolerances are achieved on such parts is vital given the safety-critical nature of many electronics applications.

Manufacturers are increasingly turning to PCE as they are under pressure to create smaller and increasingly complex precision metal components. As with any process selection, OEMs need to be aware of the specific attributes of the chosen manufacturing technology when looking at design attributes and parameters. The versatility of PCE and its unique advantages as a precision sheet metal machining technology makes it an engine for design innovation, and can truly be used to manufacture parts that would be deemed impossible if using alternative metalworking technologies.

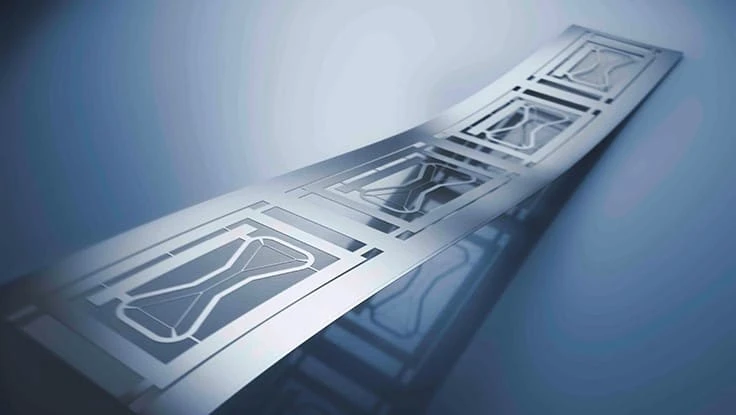

Uniquely in the industry, micrometal can process and deliver up to 800-meter-long metal strips on reel, and these are often requested in industries that already demonstrate a high degree of automation in their own processing.

Thus, the etched parts provided in reels by micrometal can be selectively coated or used by ‘Pick & Place’ at the final point of production. Such procedures are already widely implemented in the medical and automotive industries where micrometal services a number of market-leading and blue-chip OEMs.

Latest from Today's Medical Developments

- Arterex acquires Phoenix S.r.l., a leading Italian medical device solution provider

- FAULHABER’s expanded portfolio of high-performance DC motors

- NAMSA will acquire WuXi AppTec facilities in Minnesota and Georgia

- Tolomatic’s Drive Integration Tool

- Cutting Edge Innovations: Maximizing Productivity and Best Practices with Superabrasives

- The toolbelt generation

- Covestro's role in transforming cardiac care

- Practical and Affordable Factory Digital Twins for SMEs