Velo3D’s Sapphire system, Flow print preparation software, and Intelligent Fusion technology offers an end-to-end metal additive manufacturing (AM) solution, tackles product design limitations, part-to-part consistency, process control, and cost-effective manufacturing challenges.

Velo founder and CEO Benny Buller says, “Our approach relies on creating deep insights in physics fundamentals enabled by research, characterizing and understanding core mechanisms, developing intelligent process control through software simulation, and in-situ metrology.”

Three new filament additions to AM materials portfolio

SABIC added three filaments to its materials portfolio line for fused deposition modeling: Ultem AMHU1010F and Lexan AMHC620F filaments for healthcare applications; and Ultem AM1010F filament for general high-temperature applications, including tooling. These materials can be used for end-use parts as well as prototypes.

Ultem AMHU1010F filament is a polyetherimide (PEI) product, manufactured from Ultem HU1010 healthcare-grade resin, providing inherent high-heat resistance. The unpigmented filament is biocompatible (ISO 10993 or USP Class VI), and printed parts can be sterilized using gamma radiation, ethylene oxide (EtO), or steam autoclaving. It is UL94 V-0 compliant at 1.5mm and 5VA compliant at 3.0mm.

Lexan AMHC620F polycarbonate (PC) filament, healthcare-grade resins available in white, is biocompatible and can be sterilized with gamma or EtO methods. This filament meets UL94 HB rating at 1.5mm.

Both filaments deliver excellent mechanical performance and are suitable for various medical devices, from conceptual modeling to functional prototyping and end-use parts. Possible customized or personalized applications include surgical instruments, single-use devices, and casts/splints.

Ultem AM1010F, provides high-heat resistance (a glass transition temperature of 217°C) and high mechanical strength. It can be used in applications such as short-cycle injection molding tools, carbon-fiber layup tools, and general high-temperature applications. The filament is UL94 V-0 compliant at 1.5mm and 5VA compliant at 3.0mm.

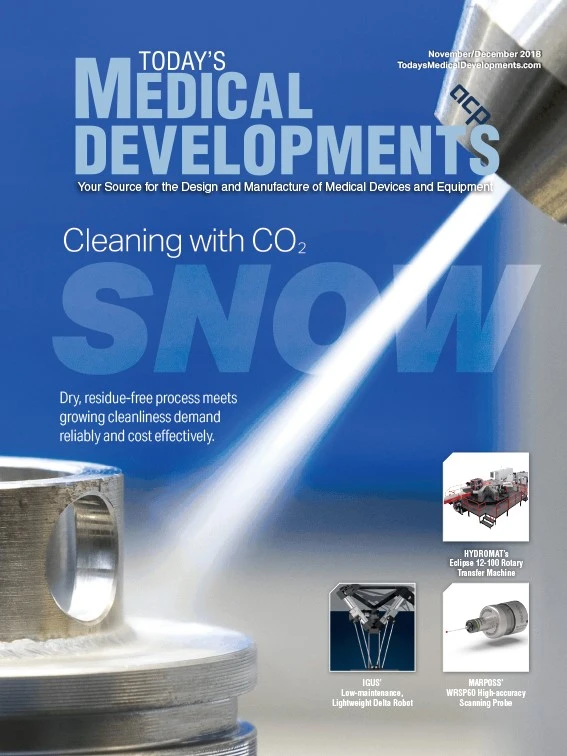

Explore the November December 2018 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- HERMES AWARD 2025 – Jury nominates three tech innovations

- Vision Engineering’s EVO Cam HALO

- How to Reduce First Article Inspection Creation Time by 70% to 90% with DISCUS Software

- FANUC America launches new robot tutorial website for all

- Murata Machinery USA’s MT1065EX twin-spindle, CNC turning center

- #40 - Lunch & Learn with Fagor Automation

- Kistler offers service for piezoelectric force sensors and measuring chains

- Creaform’s Pro version of Scan-to-CAD Application Module