INNOVATIVE MEDICAL AND YOUNGQUIST MEDICAL INSPIRE CONFIDENCE WITH ADVANCED SUB-MICRON MEASUREMENT CAPABILITIES.

If you want to get off to a fast start in the medical parts manufacturing business, it makes sense to purchase advanced CNC equipment for cost-effective, single set-up manufacturing. Then, hire experienced medical manufacturing professionals to implement and operate your manufacturing systems. Finally, guarantee that you maintain exceptionally tight tolerances while producing the goods at reasonable prices.

If you are a newcomer to medical manufacturing, you should not blame your customers for thinking that this offer sounds too good to be true. However, you can short circuit potential skepticism by equipping your quality department with advanced ultra precision, multi-sensor measurement equipment to continuously validate your high standards. This is the strategy Youngquist Brothers Inc. (YBI) employed in 2005, when it started not one, but two medical manufacturing businesses in Fort Myers, FL.

BUILD IT FIRST

YBI corporation chose to enter the medical manufacturing marketplace because of high growth potential and reasonable profit margins.

According to Innovative Medical's president, Paul McCullers, the commitment to modern plants, experienced manpower and state-of-the-art equipment were made long before the first orders were secured. "We would rather build it and tell everybody what we have rather than make empty promises," he says.

Innovative Medical, Inc, the larger of the two start-ups is a medical contract manufacturer specializing in the machining and finishing of medical implants and precision surgical tools. It is based in a 21,000 ft2 facility in Fort Myers. The company opened its doors with an initial new equipment inventory that included 20 CNC machines, installed in a Class 10,000 cleanroom.

The sister company, Youngquist Medical, also started in 2005, specializes in manufacturing implantable knees and hips, relying on four Schütte 5-axis grinders. It is housed in a 10,000 ft2 plant, in Fort Myers.

"We are very fortunate," McCullers says. "A lot of our staff members were recruited out of orthopedic and medical industries in general. Even though we are only a year-and-a-half old, we have all the expertise in-house to take a project from start to finish."

WAR ON WEAR

As for equipping the new plants, he says, "We were looking to acquire the finest machine tools and metrology equipment possible. The reasoning behind this philosophy is simple, medical implants such as hip and knee joints must last as long as possible in the human body. Any amount of variation in the part – not to mention out of spec variation – will cause the part to wear out quicker."

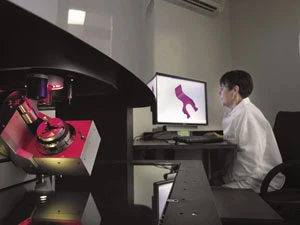

Being able to verify that medical parts are being consistently manufactured to specifications is an essential adjunct to the Youngquist start-up war on wear. After evaluating four measurement systems, they selected Mycrona multi-sensor measurement systems equipped with PCDMIS Vision software that supported all of the equipment's tactile and non-tactile measurement capabilities.

Measurement systems interpret lightingconditions and focal length to detectedges and measure distances.

Each of the four Mycrona systems purchased initially provides micron measurement resolution and the ability to measure with either tactile or vision probes. The two larger Mycrona multi-sensor systems incorporate high-resolution white light sensing in addition to a rotary table. "It all flows down to repeatability," says McCullers, "and that's what these singleset- up measurement systems give us."

MULTIPLE VALIDATION TOOLS

With advanced CNC equipment involved in prototyping, tooling and production manufacturing, there is an enormous amount of measurement and inspection that has to be processed through the Mycrona equipment. The company has a CMM and a number of smaller pieces of auxiliary equipment, but the Mycrona machines are considered to be the flagship measurement tools. They are involved in almost every part the company manufactures. There are about twelve workers at the plant that are qualified to operate these measurement systems, and five are capable of programming, too.

McCullers says, "Every part we make is unique and high-precision. Our multisensor systems give us the tools we need to quickly program and measure them with exceptional repeatability.

CONFIDENCE JUSTIFIED

Since opening its doors in 2005, the two Youngquist companies have used their high-tech multi-sensor measurement systems to repeatedly validate adherence to tight medical product specification, as promoted.

Explore the August 2007 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- LK Metrology acquires Nikon Metrology’s laser scanning and Focus software assets

- Flexxbotics’ robot compatibility with LMI Technologies 3D scanning, inspection products

- IMTS 2024 Booth Tour: Behringer Saws

- UNITED GRINDING Group to acquire GF Machining Solutions

- Mitutoyo America’s Metlogix M3 with the Quick Image Vision System

- IMTS 2024 Booth Tour: Belmont Equipment & Technologies

- Krell Technologies launches Photonics Outreach Program

- Hurco’s TM8MYi lathe