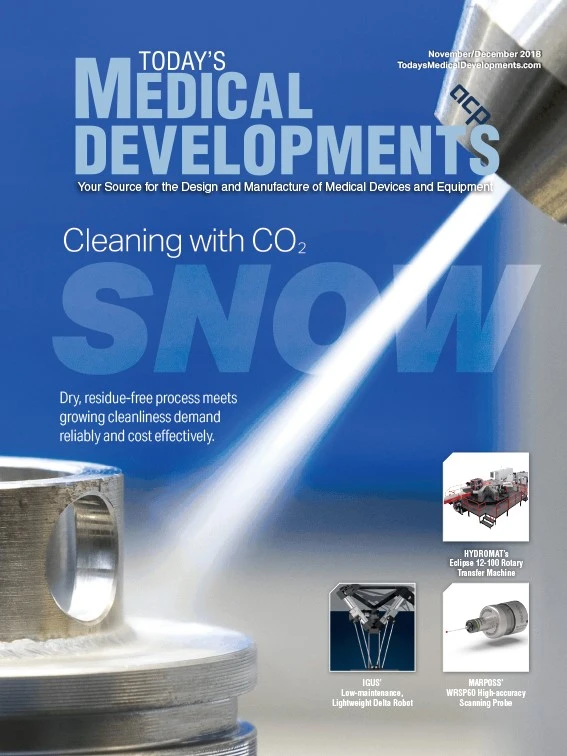

Photo courtesy of acp - advanced clean production GmbH

Medical device design and manufacturing trends require reliable, reproducible, and cost-effective cleaning solutions to handle smaller components, more complex parts, shorter product life cycles, lower product volumes, new materials/material combinations, and new or modified production processes. Manufacturers also want dry, residue-free, environmentally-neutral cleaning technology that integrates easily into production lines, Industry 4.0 manufacturing systems, and cleanrooms. And, systems must be adaptable to various tasks when material combinations or surface structures are unsuitable for wet-chemical cleaning or only certain areas of components need cleaning.

Snow jet technology from acp - advanced clean production GmbH offers a scalable cleaning system solution that easily adapts to diverse component geometries to clean selective areas or whole components.

A by-product of chemical processes and biomass energy generation, liquid carbon dioxide as a cleaning medium has a long shelf-life, supplied in cylinders or tanks.

Dry, residue-free

Liquid CO2 flows through the non-wearing, two-component ring nozzle of the system and expands upon exit to form fine CO2 crystals. A circular jacketed jet of compressed air bundles the crystals and accelerates them to supersonic speed. Uniform cleaning results are possible on large surfaces, where several nozzles are used.

When -78.5°C compressed air and snow impacts a surface it creates a thermal, mechanical, sublimation combination generating a solvent effect. These four cleaning mechanisms enable acp’s quattroClean system to remove filmic contamination, such as residues of cooling lubricants, process oils, polishing pastes, separating agents, and silicones, as well as particulate contamination – chips, dust, and abrasion. Non-combustible, non-corrosive, non-toxic CO2 snow is gentle on materials, making it suitable for delicate and finely-structured surfaces.

The jet’s aerodynamic force transports detached dirt away from the part and extracts it from the cleaning cell together with the sublimated CO2 gas. The workpieces emerge from cleaning dry, ready for additional processing or packaging.

Automation friendly

With its modular design, the compact quattroClean system can be adapted to customer requirements, allowing manual, partially-automated and even fully-automated cleaning systems to be developed for existing production, assembly, and packaging lines. Cleaning tests conducted at the acp technical center determine all the application’s process parameters, such as volume flows for compressed air and carbon dioxide, as well as the jet duration. Material properties and the contamination requiring removal are considered and these parameters can be filed as cleaning programs in the system control.

acp - advanced clean production GmbH

http://www.acp-micron.com

Explore the November December 2018 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- December Lunch + Learn webinar with LANG Technik + Metalcraft Automation Group

- IMTS 2026 runs Sept. 14-19 at McCormick Place in Chicago, Illinois

- Master Bond’s MasterSil 800Med

- ZEISS celebrates 100 years of advancing innovation in the US

- Teleflex sells acute care and urology businesses for $2.03 billion

- HANNOVER MESSE: Where research and manufacturing meet

- What’s next for the design and manufacturing industry in 2026?

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions