Development costs and times are critical considerations for today’s medical manufacturers when creating prototype parts. Accurately evaluating the geometry, design, performance, and feel of plastic injection-molded parts is necessary before creating final production molds. Typically, prototype plastic parts are created using molds made of soft steel to ensure the manufacturability and dimensional accuracy of the plastic parts and to evaluate the product’s final material. However, creating a soft steel mold is expensive and time consuming.

Development costs and times are critical considerations for today’s medical manufacturers when creating prototype parts. Accurately evaluating the geometry, design, performance, and feel of plastic injection-molded parts is necessary before creating final production molds. Typically, prototype plastic parts are created using molds made of soft steel to ensure the manufacturability and dimensional accuracy of the plastic parts and to evaluate the product’s final material. However, creating a soft steel mold is expensive and time consuming.

Challenge

Coloplast, a global medical device company, needed sample parts produced in a thermoplastic elastomer (TPE) to test the feel of a new urology device. Engineers there were uncertain about the durometer it required because the product would be squeezed repeatedly by the user, and the material’s proper compression resistance was an important factor. Coloplast approached Diversified Plastics to produce sample TPE parts using a prototype mold so it could analyze the durometer and wall thickness before proceeding to production.

Solution

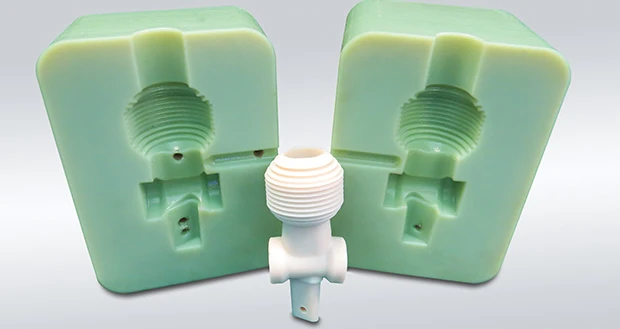

The Coloplast prototype mold would normally have been built in soft steel, but engineers at Diversified Plastics recommended producing the mold using a new, cost-effective 3D additive manufacturing process. Diversified Plastics had recently acquired a Stratasys Objet Polyjet printer that was capable of producing highly accurate injection mold components for creating prototype parts. The idea of printing the mold components was of great interest to the Coloplast R&D engineer.

3D-printed plastic molds are not designed the same as steel molds. Injection gates need to be twice as large for effective molten plastic flow and more draft is required to allow for easier part ejection from the mold. After Coloplast’s tool design file was downloaded into the Polyjet 3D printer, it took approximately 11 hours to build both halves of the mold and center core. The tooling department then inserted the printed mold components into an existing mold base.

The components could just have been bolted onto the injection machine’s mold plates, but a base already used for a similar part was available. Using this existing base saved time and reduced the overall cost because the ejector system was already in place.

The components could just have been bolted onto the injection machine’s mold plates, but a base already used for a similar part was available. Using this existing base saved time and reduced the overall cost because the ejector system was already in place.

Outcome

Engineers from Diversified Plastics presented Coloplast with a few parts molded in the actual final thermoplastic materials. After evaluating the prototype, Coloplast determined the feel of the parts was too soft to meet its requirements. With this test data, however, the engineers at the company realized what needed to be done to create acceptable parts for their new urology device trainer. Coloplast decided to revise the product design to thicken the wall sections, so the part would be slightly stiffer. It was also decided that a second prototype mold for further testing was not necessary before creating the final production mold. The whole process, from initial conversations with Coloplast, through mold production, to final product prototype, took just five business days.

Since TPE is flexible, it was impossible to machine a prototype, and building a soft steel mold that may not have met the requirements would have been expensive. Using a mold made with 3D additive manufacturing technology to determine if the design was going to meet product requirements saved thousands of dollars and weeks of time.

Diversified Plastics Inc.

www.divplast.com

Stratasys Ltd.

www.stratasys.com