High-performance, productive EDM series

The Cut E Series incorporates a range of technologies that help medical manufacturers increase their flexibility and accelerate their time to market. These include large-touchscreen human-machine interfaces (HMI) that are intuitive in operation and feature onboard Intelligent Collision Protection, built-in machining strategies, and flexible job management. Information about geometries, machining processes, and command programs is processed in a single file, allowing jobs to be transferred among different machines within the Cut E Series. The machines then automatically manage all necessary modifications.

More than 10 automated measurement cycles are available to assist with workpiece preparation and the machines’ onboard AC CAM Easy systems allow operators to prepare ISO files and post-process them into a job during machining.

The Cut E Series features the Intelligent Power Generator (IPG) to improve cutting speed, precision, and surface quality. The machines can use dedicated wire for decreased part cost and increased throughput, and the Power-Expert modules automatically determine the optimal power to send through the wire. The Corner Strategy module automatically adjusts parameters during changes in direction to produce sharp angels and small radii. These features combine to reduce cutting times by up to 18% compared to standard machines.

GF Machining Solutions

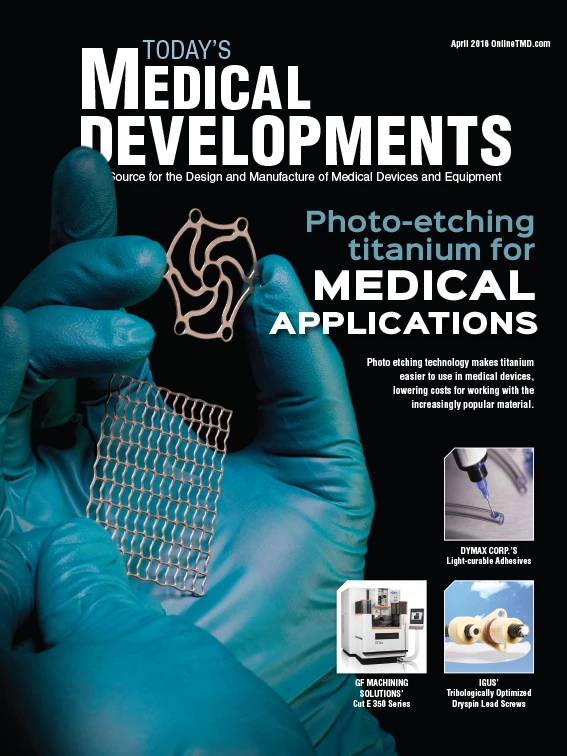

Light-curable adhesives

Light-curable adhesives designed for catheters, tube sets, reservoirs, respiratory masks, syringes, and oxygenators are solvent-free, USP Class VI, and ISO 10993 biocompatible. They incorporate See-Cure color-change technology and Ultra-Red fluorescing technology into one light-curable product, offering on-demand curing with cure confirmation and post-cure bond-line inspection.

Dymax Corp.

www.dymax.com

Lightweight lead screws

Dryspin lead screws feature tribologically optimized plastic lead screw nuts and hard anodized aluminum screws. Screw diameters ranging from 6mm to 20mm are available, as are several lead screw nut types created from self-lubricating iglide materials, including anti-backlash options. Screws are available in several thread options, and all lead screw sizes previously available only in stainless steel are now available in lightweight anodized aluminum.

igus

Explore the April 2016 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Machine learning framework enhances precision, efficiency in metal 3D printing

- SkillMill – 60-year-old milling machine with digital twin

- Lumetrics’ OptiGauge II EMS

- EMI completes installation of 128-axis CNC turning & milling machine

- Ottobock invests in innovative technologies from MIT start-ups

- Air Turbine Technology's high-speed live tools for Swiss Lathes

- Sandvik announces several software acquisitions

- Dart Controls’s EZ VFD, variable frequency drives