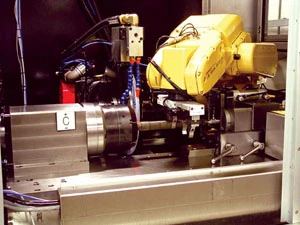

Drake Manufacturing's new GS:TE-LM thread grinder fitted with a robot load/ unload system provides maximum throughput for high-volume production of ground threads. The GS:TE-LM is a full helix thread grinder equipped with many new machine design and grinding technologies, including a 180° power helix, linear motors and ways, the latest Fanuc control, acoustic touch dressing, automatically generated wheel forms, and a mineral filled cast polymer base.

According to Drake, the grinder is applicable for taps, multi-start worms, electronic steering components, fast-lead ballscrews, feed and bone screws, gear boxes, transmissions, and speed reducers.

The auto load system consists of an infeed conveyor, robot with dual grippers, and an exit conveyor. The infeed conveyor and grippers allow fast changeovers on families of parts. During the cycle, the robot loader lifts a new blank off the infeed conveyor and deposits a finished part on the exit conveyor at the same time. Changeovers are coordinated with Drake's PartSmart programs. The robot load system is pre-programmed to automatically respond to part dimension changes. The system can conform to customer restocking intervals and can be easily integrated into manufacturing cells. The entire grinding and load/unload sequence can be programmed into the system and controlled automatically.

Drake Manufacturing Services Inc. Warren, OH drakemfg.com Booth #B-7407

Explore the July August 2006 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Kistler offers service for piezoelectric force sensors and measuring chains

- Creaform’s Pro version of Scan-to-CAD Application Module

- Humanoid robots to become the next US-China battleground

- Air Turbine Technology’s Air Turbine Spindles 601 Series

- Copper nanoparticles could reduce infection risk of implanted medical device

- Renishaw's TEMPUS technology, RenAM 500 metal AM system

- #52 - Manufacturing Matters - Fall 2024 Aerospace Industry Outlook with Richard Aboulafia

- Tariffs threaten small business growth, increase costs across industries