In medical fields that deal directly with human life, the requirement for precision equipment is absolute. For the control mechanisms of medical instruments such as MRI, CT scanners or X rays, which examine the inside of the human body and brain, precise linear motion guides are designed into equipment to help doctors take accurate readings and provide treatments such as radiation therapy. Linear motion is also used in a wide range of medical analysis machines including DNA analysis and blood analyzers.

Linear Motion Device Selection

Many factors go into an informed decision on selecting which linear motion device to use. Besides understanding the basic functions, realizing the different types of applied load present in the system and the linear motion device's capability to handle these loads directly affect the selection. Several factors can help make a comparison. To calculate safety factors and predicted service life, linear motion device manufacturers typically employ a load-rating system for different styles and sizes.

These ratings help draw comparisons between different linear motion device styles. To calculate safety factors, the static load rating is considered. While exact definitions vary from manufacturer to manufacturer, the static load rating is typically defined as the maximum allowable load that can be applied, whether that load is stationary or moving. Minimum recommended safety factors are based upon whether the system is typically stationary or moving, and if there is impact or twisting loads present.

To calculate service life, the dynamic load rating is considered. The most common definition of the dynamic load rating is the maximum allowable load, of constant magnitude and direction that yields a pre-determined distance of linear travel before the mating surface fatigue begins.

Other safety factors to be considered include extreme loads, shocks, impacts, stroke and duty cycles, vibrations and speed. Once these basic considerations have been reviewed we can move on to style selection.

Linear Motion Device Style Selection

The most common styles include: Sliding Guideway, Ball Bushing, Recirculating Ball Guideway, and Recirculating Roller Guideway.

Sliding Guideway is considered to be the oldest however still reliable linear motion device. These slides are extremely rigid, and it boasts the highest load carrying ability. But the Sliding Guideway requires a larger driving force and a large amount of lubricant to avoid seizure.

Ball Bushings are available in two styles: closed and open. The closed type features a ground round shaft that serves as the bearing surface, supported at the ends only. The open ball bushing can be configured from end to end for unlimited travel. Ball Bushings have 1/13th load capacity compared with the Recirculating Ball Guideway due to bearing ball contact design.

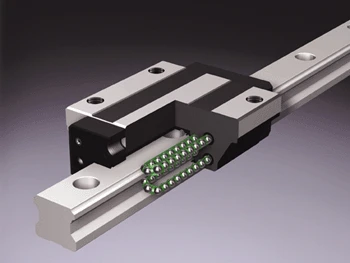

Recirculating Ball Guideway has two different designs: Gothic-Arch design and Circular Arc Design. Both designs have bearing balls between bearing block & rail, and similar load capacity, but different characteristics.

Gothic-Arch design is ideal for applications that do not need to carry a heavy load or impact. Gothic-Arch design has less forgiveness characteristics against misalignment or overhang load. Therefore, misaligned installation or improper preloaded conditions due to misalignment or overhang loaded condition may shorten service life due to weariness or fatigue.

Circular Arc design is used for light, medium and heavy load application. Circular Arc design has more forgiveness characteristics against misalignment installation, preload or shock load. This characteristic helps easier installation and less failure due to weariness or fatigue. Therefore, Circular Arc designed Recirculating Ball Guideway is the most reliable design for any type of application.

Recirculating Roller Guideway exhibits higher load-carrying capacity compared to their ball counter-parts and are quite rigid. This design has less forgiveness characteristics com45 pare with any Ball Guideway design. However, due to higher load capability by bearing rollers, it may be able to downsize for compact design or possibly increase rigidity without changing dimensions.

Current Linear Motion Technology

Addressing specific needs of the medical market that are: accuracy, quieter operation and virtually maintenance free, the most updated linear motion devices will use a cage to separate and align recirculating ball bearings. This offers a smoother and more consistent gliding motion. Caged Balls eliminate the heat associated with ball-to-ball friction and allowing for increased speed and longer product life. Separating the balls prevents the breakdown of oil and provides for quieter operation, higher speed, and longer running life. The cage also acts as a reservoir for lubricants that achieves virtually "Maintenance Free" condition.

THK – Pioneering LM Guide Medical Solutions

THK has developed a line of LM guides (Linear Motion Guides) that have tremendous benefit to the medical industry. The LM Guide, which is capable of providing smooth, quiet and clean operation is considered very effective, not only for its functionality, but also for providing comfort to the patient. For example, a patient undergoing an MRI test is less nervous throughout the process because the imaging machine emits less loud unpleasant noises. The potential of THK's products in this field is continuously increasing; for example, they are used in surgical operations supporting robots that aid surgeons and in nursing products that support an aging society.

THK's product innovation that is increasingly used in medical applications is THK's Caged Ball technology. This patented Caged Ball technology isolates each of the load carrying re-circulating balls in our LM guides in an individual cage. THK's Caged Balls result in higher speed capabilities and, with 1/10th the torque deviation of standard LM guides, greatly improved positioning accuracy.

Truly an asset to the medical industry, THK's Caged Ball technology virtually eliminates both noise and maintenance. In fact, we have customers using our SSR LM guide with Caged Ball technology in the latest imaging devices and positioning systems for radiation treatment for those two specific reasons.

Furthermore, THK's linear motion products have begun to be utilized in DNA analyzers in the most advanced medical fields. The DNA field is expected to play a pivotal role in the fuapplicature medical field by offering the most suitable treatment for each individual and analyzing genes to cure intractable diseases. For developing the indispensable DNA chip for such gene analysis, the high-speed drive linear motor became an extremely effective technology and it will help to facilitate further development in this field. TMD

Explore the November 2005 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Robot orders accelerate in Q3

- Pro Shrink TubeChiller makes shrink-fit tool holding safer, easier

- Revolutionizing biocompatibility: The role of amnion in next-generation medical devices

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.