Using technology developed for the XM-60 multi-axis calibrator, the XM-600 laser measurement system offers enhanced capability to connect directly with universal coordinate measuring machine (CMM) controllers (UCC). This allows faster and easier error mapping, measuring all six degrees of freedom from a single setup, in any orientation for linear axes. The XM-600 communicates easily with UCC software during calibration to quickly build a complete error map of the CMM, supported by UCCsuite V5.4 and higher. The XM-600 has the same compatibility with CARTO software as the XM-60.

Renishaw Inc.

http://www.renishaw.com

Mill-turn control technology

The TNC 640 mill-turn control features touch technology, allowing the user to navigate quickly through long lists, programs, tables, and other content using gestures. Programming and 3D test graphics can be moved directly on the screen – dynamically, smoothly, and without jerks.

The minimum requirement for NC Software version is 340 59x-07 SP2. The hardware enabling touch control are the MC8532 main computer and the BF 860 color flat-panel.

The MC 8532 features A 19" touchscreen, an Intel Core i7 processor with 1.7GHz on SSDR, and 4GB RAM memory. The BF 860 offers 4 USB ports.

Heidenhain Corp.

http://www.heidenhain.us

Clamping levers with eccentrical cam

GN 927 clamping levers feature an eccentrical cam, in tapped-type and threaded-stud versions. The RoHS-compliant levers offer torque-free rapid clamping and releasing, and movement cannot exceed the maximum clamping position. There are no loose components, since all are assembled and mounted in order. Thrust forces of up to 1.8 lb (8N) can be obtained.

JW Winco Inc.

http://www.jwwinco.com

Ultrasonic cleaning

The GMC stainless-steel ultrasonic cleaning system achieves chemical compatibility with aggressive caustic and acidic agents. Versions of the system can accommodate parts with one dimension up to 35", up to 125 lb. The line’s two sizes are self-contained, supported on casters, and operate from commonly available power supplies, making them easy to move where needed for in-place or utility cleaning. GMC systems include a pump and dual stainless cartridge filtration, a surface sparger, automated controls for heat, pump and ultrasonics, a lid, and one standard basket. A drip pan drains one basket of parts, while cleaning another.

Cleaning Technologies Group

http://www.ctgclean.com

Explore the October 2018 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Manufacturers’ technology adoption & attitudes survey

- FOBA Laser Marking + Engraving’s F.0100-ir ultrashort pulse laser

- #57 - Manufacturing Matters - Agile & Robust Supply Chain Management with Lisa Anderson

- Manufacturing leaders are bullish on AI for supply chain growth

- Take control of your manufacturing business despite supply chain turmoil

- Strengthening the defense maritime industrial base for national security, economic resilience

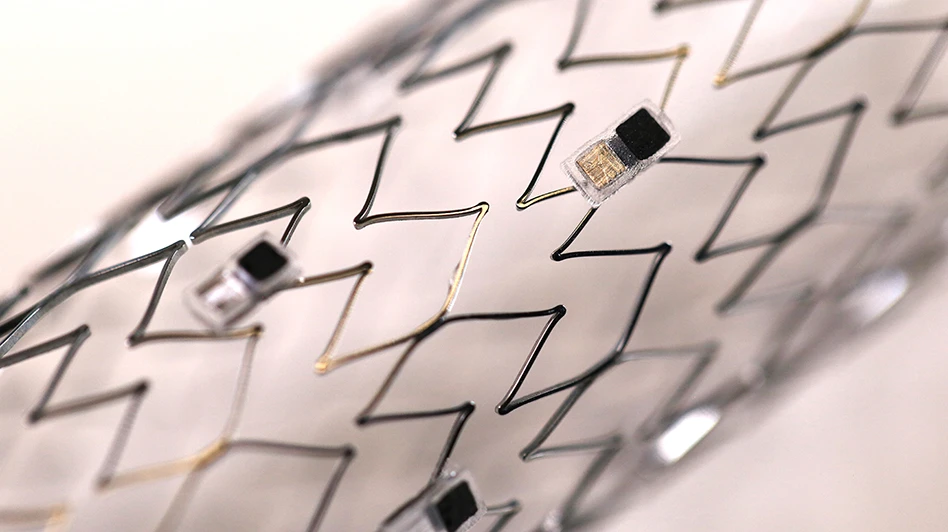

- Hacker-proofing smart implants

- Register now to learn solutions for high-temperature aerospace machining challenges