Kassow Robots

Kassow Robots, a developer of 7-axis cobot solutions for machine tending, material handling, and related applications, has partnered with Norwood, Massachusetts-based Gibson Engineering, a subsidiary of Applied Industrial Technologies. Gibson Engineering is a value-added distributor of automation solutions serving manufacturers in all industries in the northeastern U.S., from Maine to Maryland.

The KR series of lightweight 7-axis collaborative robots supplements Gibson Engineering’s solutions to efficiently complete light manufacturing operations in the medical, semiconductor, and electronics industries.

“Gibson Engineering’s long-established operation gives Kassow Robots the opportunity to work with world-class manufacturers in the U.S. that can benefit from strong, fast, and simple cobots,” says Dieter Pletscher, the head of global sales at Kassow Robots.

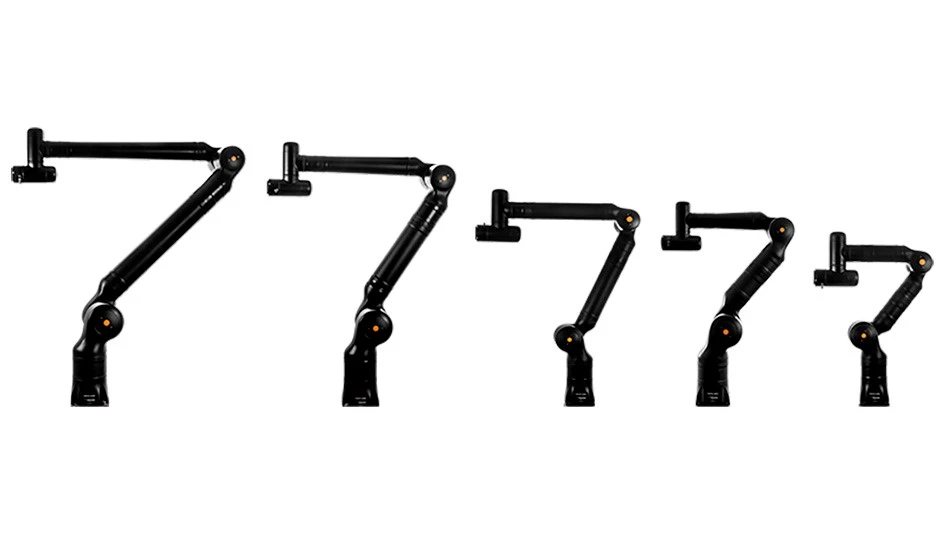

The 7-axis cobots offer speed and power combined with a long reach and a high degree of flexibility to work in tight and awkward spaces. The KR series can handle payloads up to 18kg and reach up to 1,800mm, allowing customers to automate a variety of physically demanding and/or repetitive tasks. The seventh axis enables continuous dispensing, welding, and material removal applications, regardless of access angle, without the need to reorient the arm.

“The KR 7-axis cobots use workspaces efficiently and give programmers more options for completing tasks than traditional 6-axis devices,” says Rob MacDonald, director of sales and marketing at Gibson Engineering. “The combination of performance, ease of use, and safety makes the Kassow cobots a great addition to our product portfolio.”

Small- and medium-sized enterprises (SMEs) without robotics specialists can carry out complex automation and programming cost-effectively and independently with Kassow Robots solutions. The cobots are perfect for limited-space retrofits and applications such as machine tending, pick-and-place tasks, quality inspection, and palletizing.

Latest from Today's Medical Developments

- How to Reduce First Article Inspection Creation Time by 70% to 90% with DISCUS Software

- FANUC America launches new robot tutorial website for all

- Murata Machinery USA’s MT1065EX twin-spindle, CNC turning center

- #40 - Lunch & Learn with Fagor Automation

- Kistler offers service for piezoelectric force sensors and measuring chains

- Creaform’s Pro version of Scan-to-CAD Application Module

- Humanoid robots to become the next US-China battleground

- Air Turbine Technology’s Air Turbine Spindles 601 Series