Jamco America

Jamco America, Inc., one of the most experienced aircraft interior products supplier and turnkey integrator in the aerospace industry, highlights its extensive machining capabilities that uniquely enable the company to meet rapid turnaround times and extensive customization needs. In addition to internal product development and fabrication projects for its aerospace customers, the Jamco America machine shop is available for contract projects from the medical industry.

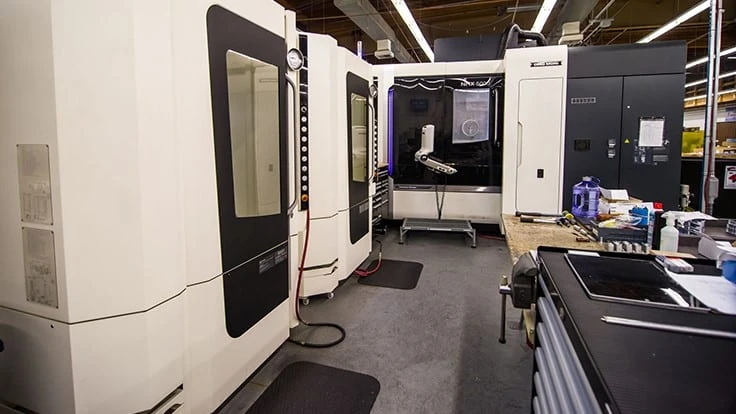

In nearly 30 years of operation, the Jamco machine shop has expanded its capabilities from basic machining to extensive, cutting edge equipment. The shop’s capabilities include: sheet metal bending, profiling, and forming; countersinking, dimpling, riveting, and other preparations for sub-assembly; large 4-axis Horizontal milling and machining; smaller 3- and 4-axis Vertical machining; and lathe turning for round components. The large 4-axis machine centers hold 240 tools each, and are accompanied by an automated 36 pallet cell, for highly flexible, efficient milling 24/7, ensuring rapid turnaround time.

One of the shop’s most unique capabilities is delivered by its freeform CNC tube bender, installed in summer 2020. This machine forms a round tube into a unique tubing frame, and is used to produce Jamco’s industry-leading Venture business class seats with embedded aluminum edge trim. The shop also houses a digital cutter/router for composite materials, open cell core, textiles, and more. Used traditionally in the sign-making industry, Jamco has adapted this technology for aircraft seating and other innovative projects.

Thanks to its extensive machining capabilities, Jamco America is able to deliver products in unrivaled rapid lead times. This rapid turnaround enables fast-paced product development, a necessity in aerospace and other highly demanding industries. What’s more, the machine shop’s extensive capabilities enable Jamco to offer ultimate customizability, helping customers to differentiate their products from competitors.

Latest from Today's Medical Developments

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Robot orders accelerate in Q3

- Pro Shrink TubeChiller makes shrink-fit tool holding safer, easier

- Revolutionizing biocompatibility: The role of amnion in next-generation medical devices

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.