1. What makes the SNAP video-based metrology system a good fit for today’s manufacturing measurement requirements?

The SNAP uses a large field of view (LFOV) lens providing a much larger area of measurement without stage movement. SNAP optics provide much greater depth of focus than traditional video-based systems, allowing measurement of features at different distances from the lens to remain in focus without moving the lens. Both characteristics make measurement faster, as the software processes any feature within the FOV at lightning speed. This combination of optical characteristics is only applicable to metrology when the optics are highly telecentric, meaning the zone in which the distance from the lens and the location within the FOV do not appreciably change the size or shape of the feature being viewed.

All video measurement systems measure the image of the part, not the part. Highly telecentric optics and a collimated light source create the optimum image for accurate measurement.

2. How do SNAP optics fit in with day-to-day measurements?

A manufacturer of pneumatic and electric tools has a cell that machines and broaches ratchet heads. The ratchet head thickness for the various drives differs about 0.700" between the shortest and tallest. Without SNAP’s exceptional depth of focus, the stage would have to reposition to focus on each part. The large FOV negates the need for a moving stage, completing the measurement in 5 seconds. This SNAP metrology system monitors the entire cell’s output. Operators simply place the part on the SNAP stage and press one button.

3. Is the SNAP limited to a single magnification, stage size?

The SNAP product line offers various lenses and stage sizes to address metrology challenges. The simplest system is equipped with a single lens, no moving stage, and a manual Z-axis, such as the model monitoring three machine tools and three broaching machines.

SNAP-X software digitally magnifies any lens utilized. Individual lenses provide magnification appropriate for features being measured. SNAP DM (Dual Mag) systems offer two lenses on a single SNAP, increasing the magnification range automatically by changing lenses. Changing magnification and magnification range within a program is an industry leading capability.

4. How are SNAPs calibrated/ compensated?

Our approach uses a NIST-traceable standard to calibrate the FOV and to compensate for any FOV errors, however small, by mapping each magnification for all lenses to the known artifact values. QVI/OGP is one of the pioneers of this technique, adding real value to the SNAP.

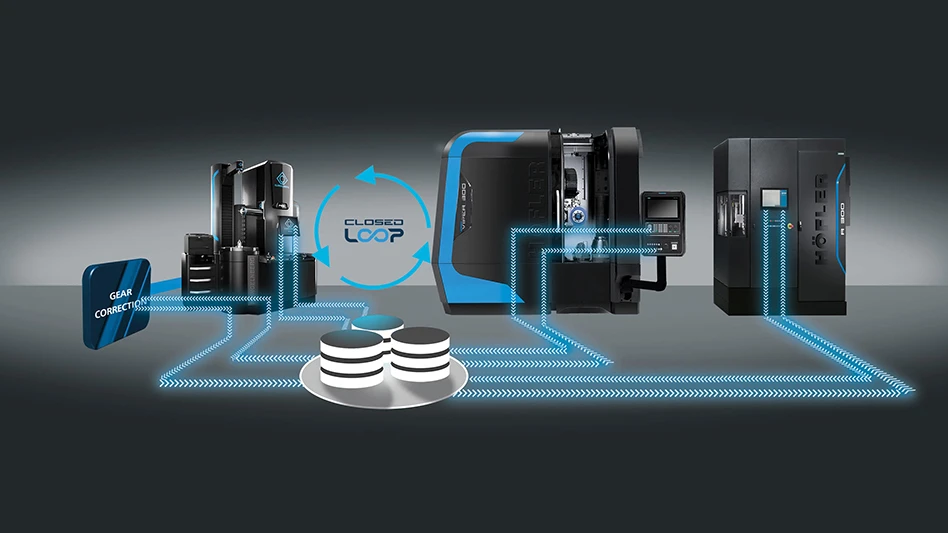

5. Are SNAPs adaptable to automation?

The speed of measurement, small footprint, robust construction, and ability to communicate with other devices are all characteristics well-suited for automation.

Cycle times are decreasing, so measurement times must decrease too. Concurrently, tolerances are shrinking. The SNAP hits the sweet spot of speed and accuracy for many metrology applications.

As automation grows, and metrology becomes standard in most automated lines, the SNAP is an excellent solution to many challenges.

FOR MORE INFORMATION:

https://www.ogpnet.com

Explore the June 2019 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- MedTech Innovator welcomes five new industry partners

- First Article Inspection for quality control

- The manufacturing resurgence is here – are you ready?

- Workholding solutions for your business

- ZOLLER events will showcase the company’s cutting-edge innovations

- THINBIT’s MINI GROOVE ‘N TURN Acme threading inserts

- CMMC Roll Out: When Do I Need to Comply? webinar

- Metabolic research uses Siemens gas analyzers to deliver results with 99.9999% resolutions