Modern joint implants restore pain-free mobility to patients with chronic degenerative joint disease, drastically enhancing their quality of life. To ensure long-term mechanical stability, artificial joints are made from materials containing a range of metal alloys. A crucial factor in determining an implant’s long-term effectiveness, however, is its integration into surrounding bone tissue. Studies on implant stability show that friction between articulating surfaces (bearing surfaces) can form metal debris. Wear debris can lead to osteolysis – destruction of bone around the implant – which can prematurely loosen the implant.

Using complex analytical techniques, a group of French and German researchers from Charité – Universitätsmedizin Berlin, led by Dr. Sven Geißler of Charité’s Julius Wolff Institute for Biomechanics and Musculoskeletal Regeneration and BIH Center for Regenerative Therapies, observed how different metals released from joint implants accumulate in surrounding bone tissue. Findings showed a steady release of metals from various implant components. In contrast to previous assumptions, this wasn’t related to the degree of mechanical stress involved. The researchers’ findings will optimize future implant materials and enhance their safety.

Researchers studied spatial distribution and local toxicokinetics of metallic wear and corrosion products within surrounding bone tissue, using unique, synchrotron-based X-ray fluorescence imaging.

“Our work has enabled us to show, for the first time, that both particulate and dissolved metals released from arthroplasty implants are present in the surrounding bone and bone marrow at supraphysiological levels,” Geißler says. “Therefore, the collagen-rich layer which encapsulates the implant after surgery does not separate these metals from human tissue to the extent previously assumed.”

Researchers collected minute bone and bone marrow samples from 14 patients undergoing hip or knee arthroplasty procedures. They then determined the qualitative and quantitative composition of samples using X-ray fluorescence. This technique provides unique insights into the concentration, distribution, location, and accumulation of metallic degradation products such as cobalt, chromium, or titanium in adjacent bone and bone marrow. The extremely bright and intensely focused X-ray beam was achieved by the synchrotron radiation source at the European Synchrotron Radiation Facility (ESRF), in Grenoble, France, (https://www.esrf.eu) the only particle accelerator to offer a spatial resolution of 30nm.

“Our study has made a major contribution to the improvement of risk-benefit evaluation of medical devices. It has shown that evaluations shouldn’t only comprise biocompatibility testing of raw materials – biocompatibility testing should extend to wear and corrosion products,” Geißler explains.

Researchers plan to conduct additional studies to investigate the biological consequences of metal release on bones and bone marrow. Simultaneously, they will develop new approaches to facilitate reliable preclinical testing of implant materials using human cells and engineered tissues.

Charité – Universitätsmedizin Berlin

https://www.charite.de/en

European Synchroton Radiation Facility

https://www.esrf.eu

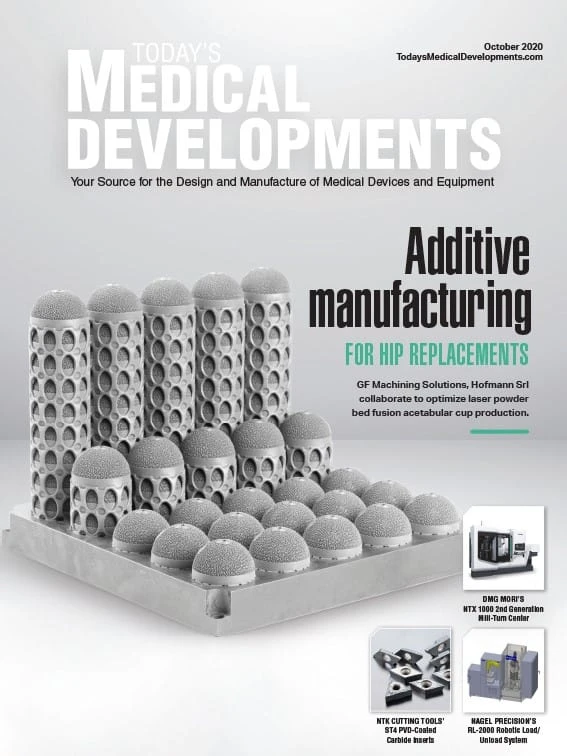

Explore the October 2020 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Pioneering battery-free cardiac implants

- KBC Tools & Machinery marks its 60th anniversary, Founder’s Day

- Address the challenges of machining high-temperature aerospace components

- Elevate your manufacturing operations with April’s Manufacturing Lunch + Learn

- AdvaMed statement on tariff announcement

- Collets – Not all are created equal

- ENGEL expands production capacities in the Americas; new plant opened in Mexico

- MFI brings fast, high-polishing additive parts finishing to Rapid + TCT 2025