Never rest, never stand still. It's an attitude one job shop in the "orthopedic capital of the world" has applied since its inception in 1988. Micropulse Inc. of Columbia City is located near Warsaw, IN, home to many major suppliers of orthopedic implants, instruments and related high-precision medical apparatuses.

Technology developments at Micropulse have followed the same business model as other aspects of the company. In the medical market, several factors present unique challenges for the shops that supply its machined metal parts. Material composition of the parts is the first challenge, as titanium, stainless, cobalt chromium, zirconium and now Nitinol (a nickel-titanium derivative) possess what's called shaped memory and behave in a manner similar to human muscles. The R&D and prototyping process for medical parts, especially implants and surgical instruments, is among the most rigorous of any industry in the world. Plus, when the quantities produced are often very low, the extreme challenge for the job shop is profitability.

This last factor is by far the most daunting, as even the top quality shops wrestle with cost issues. Strategies used to overcome this challenge are many, but Micropulse has concentrated on two: the introduction of more automation into their process, and the acquisition of more sophisticated machine tools that are capable of performing multiple functions.

On the automation front, President and founder Brian Emerick notes that Micropulse has designed, engineered and built a number of dedicated automation devices, such as auto-advance tooling for the electrodes on their sinker EDMs.

Sales engineer Randy Sible notes, "We need to cost justify at every turn, as our customers demand it for their own price competitiveness in the market. Just making a great part and delivering it on time isn't enough. The advancements we've made in the automation area have substantially reduced our time-to-part and our own cost structures, while maintaining the highest quality in the industry."

Emerick discovered a machine that combined milling, grinding, belt sanding and polishing altogether, on one pendulum slide with CNC rotary axis. The machine wasn't simply a glorified tool changer, it had true five-axis capability and was touted for form tool production,where both axial and radial clearance angles were critical. Micropulse was performing all of these functions on individual machine tools. It was proving to be too slow and too expensive, when the part complexity reached certain levels, on a product such as a knee joint or hip broach.

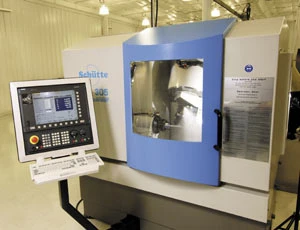

Emerick noted that the Schütte WU 305 Linear universal tool and cutter grinder had the ideal rigidity, precision, small footprint, coolant filtration system and sophisticated CNC that Micropulse needed. The CNC, a Siemens SINUMERIK 840D, offered the flexibility and open architecture, allowing all the different functions of the machine to be performed, while handling the various proprietary part design and machining programs used by Micropulse and its customers.

Also, the unique filtration system was capable of handling the milling chips, grinding dust, sandpaper grit and polishing rouge generated by the various machining operations. While a ball-screw version of the machine had been on the market for several years, this version of the Schütte cutter grinder has Siemens linear motors on all five axes, providing a dealmaking difference for Micropulse.

"Randy and I realized this machine would allow us to enter that knee joint, hip broach and other end product market areas where we'd not been competing," Emerick notes. Within the first year after installation, the Schütte cutter grinder has already helped achieve substantial business gains for Micropulse, from old and new customers.

The training on the machine was provided by Schütte at its factory in Cologne, Germany, as well as its American subsidiary, Schütte TGM in Jackson, MI, a facility managed by company director, Dave Brigham.

Brigham observes, "With the five-position wheel changer and five-axis pendulum slide, this machine can produce the sophisticated surface profiling that Micropulse needs in one operation. The setup time savings alone, versus going from machine to machine are incredible. It's as if this machine was built for applications such as the knee joints, hip broaches and other products that Micropulse and similar companies in the medical market want to make."

The Siemens CNC is the only control capable of processing the software for the cylindrical grinding on our cutter grinder, plus the drive system allows Micropulse to achieve this feature and the others, all on the same machine."

The Schütte cutter grinder is applicable to the regrind or manufacture of any cutting tool, from simple drills and end mills, to complex step drills and profile tools. In the medical industry specifically, the machine is currently producing knee, hip and shoulder components plus reamers, rasps, broaches and other medical cutting instruments

A typical job run by Micropulse on this machine, according to Randy Sible, might involve a Pro-E, Mastercam, Unigrafix or SolidWorks program. Usually, a working model is supplied by the customer, which is then analyzed by the production engineering team at Micropulse. Changes might be recommended, based on the machinability of the material, the particular configuration of the part, or the process flow aspects of the job.

Sible explains, "The SIGS and the Vericut programs accommodate the machine's kinematics in every way, so there's less chance of error. With the lockout keys on the Siemens control, function access is limited, so there's no chance of changing the machine functions or the software on the cutting program, except by the dedicated operator and other select individuals.

"With the very expensive materials we run and the highly proprietary nature of many customer parts, this is important to us." Sible also notes that the Siemens control and drive packages work in concert to maintain superior speed and accuracy.

"I've personally worked with several other CNCs in the medical machining market and the Siemens control is very impressive. The large look-ahead feature keeps speeds optimized, while both the hard and soft set-up times are reduced because of the integration software and the plain language inputs."

Explore the June 2007 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- HERMES AWARD 2025 – Jury nominates three tech innovations

- Vision Engineering’s EVO Cam HALO

- How to Reduce First Article Inspection Creation Time by 70% to 90% with DISCUS Software

- FANUC America launches new robot tutorial website for all

- Murata Machinery USA’s MT1065EX twin-spindle, CNC turning center

- #40 - Lunch & Learn with Fagor Automation

- Kistler offers service for piezoelectric force sensors and measuring chains

- Creaform’s Pro version of Scan-to-CAD Application Module