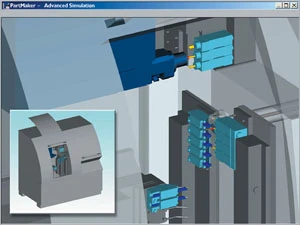

The newest version of PartMaker software features a full machine simulation module which allows the user to view a realistic 3D model of the machine for which they are programming a part.

This module provides improved error checking and collision detection to PartMaker users by allowing them to perform an even more robust machining simulation than currently offered. The machine model being simulated incorporates machine specific tool holders and attachments to assure that any possible collisions that could occur on the machine will be detected off-line on the user's PC. PartMaker is a Knowledge Based Machining system, allowing it to remember the tools, material and process information necessary to machine individual part features. It also improves efficiency by placing the emphasis on tool management functions.

PartMaker Software/ IMCS Inc. Fort Washington, PA partmaker.com Booth #D-3106

Explore the July August 2006 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Kistler offers service for piezoelectric force sensors and measuring chains

- Creaform’s Pro version of Scan-to-CAD Application Module

- Humanoid robots to become the next US-China battleground

- Air Turbine Technology’s Air Turbine Spindles 601 Series

- Copper nanoparticles could reduce infection risk of implanted medical device

- Renishaw's TEMPUS technology, RenAM 500 metal AM system

- #52 - Manufacturing Matters - Fall 2024 Aerospace Industry Outlook with Richard Aboulafia

- Tariffs threaten small business growth, increase costs across industries