University of Wisconsin-Madison engineers found a way to simultaneously mitigate three types of defects in parts produced using laser powder bed fusion (LPBF), an additive manufacturing (AM) technique.

“Previous research has normally focused on reducing one type of defect, but that would require the use of other techniques to mitigate the remaining types of defects,” says Lianyi Chen, an associate professor of mechanical engineering at UW-Madison. “Based on the mechanisms we discovered, we developed an approach that can mitigate all the defects – pores, rough surfaces, and large spatters – at once. In addition, our approach allows us to produce a part much faster without any quality compromises.”

Multiple industries are increasingly interested in using AM to produce metal parts with complex shapes that are difficult or impossible to create using conventional methods. However, a big challenge is metal parts created with AM can have defects such as voids, rough surfaces, and large spatters that significantly compromise the finished part’s reliability and durability. These quality problems prevent 3D-printed parts from being used for critical applications where failure isn’t an option.

By providing a path for simultaneously increasing part quality and manufacturing productivity, the UW-Madison team’s research could lead to widespread industry adoption of LPBF.

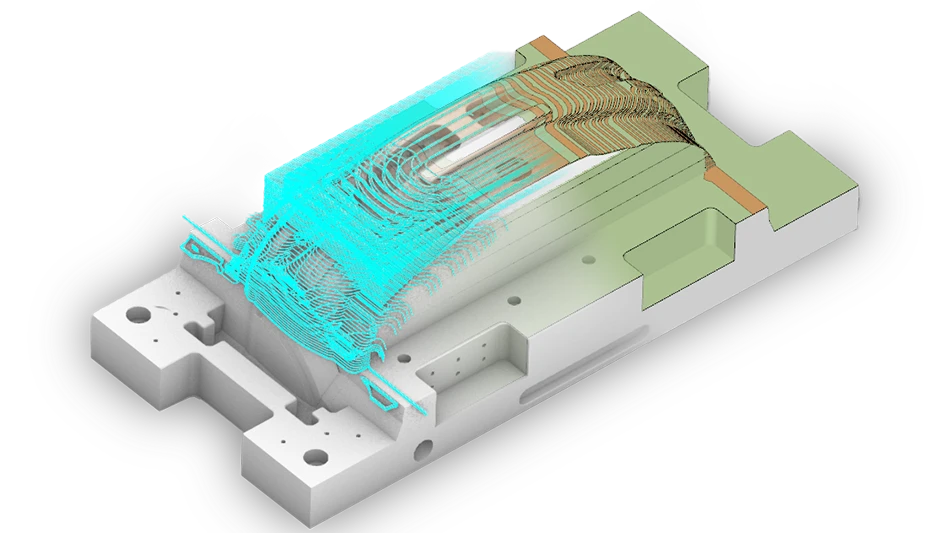

LPBF uses a high-energy laser beam to melt and fuse thin layers of metal powder, constructing a part layer by layer from the bottom up. In this research, the UW-Madison team used an innovative ring-shaped laser beam, provided by nLight, instead of the usual Gaussian-shaped beam. The ring-shaped laser beam played a key role in this breakthrough – as did critical in-situ experiments, says Jiandong Yuan, the lead author of the paper and a Ph.D. student in Chen’s group.

To see how the material behaved within the part as it was printing, researchers went to the Advanced Photon Source, an ultra-bright, high-energy synchrotron X-ray user facility at Argonne National Laboratory. Combining high-speed synchrotron X-ray imaging, theoretical analysis, and numerical simulation, the researchers revealed the defect mitigation mechanisms, which involve phenomena that reduce instabilities in the laser powder bed fusion process.

The researchers also demonstrated they could use the ring-shaped beam to drill deeper into the material without causing instabilities in the process. This enabled them to print thicker layers, increasing the manufacturing productivity.

“Because we understood the underlying mechanisms, we could more quickly identify the right processing conditions to produce high-quality parts using the ring-shaped beam,” Chen says.

The research is covered in Science Direct:

https://www.sciencedirect.com/science/article/pii/S0890695524001184.

Lianyi Chen is the Kuo K. & Cindy F. Wang Associate Professor of mechanical engineering.

Collaborators from UW-Madison include Qilin Guo, Luis Escano, Ali Nabba, Minglei Qu, Junye Huang, Qingyuan Li, Allen Jonathan Román, and Prof. Tim Osswald. Samuel Clark and Kamel Fezzaa from Argonne National Laboratory also collaborated on this project.

This work was supported by the National Science Foundation and the Wisconsin Alumni Research Foundation.

University of Wisconsin-Madison

https://www.wisc.edu/

Explore the January/February 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

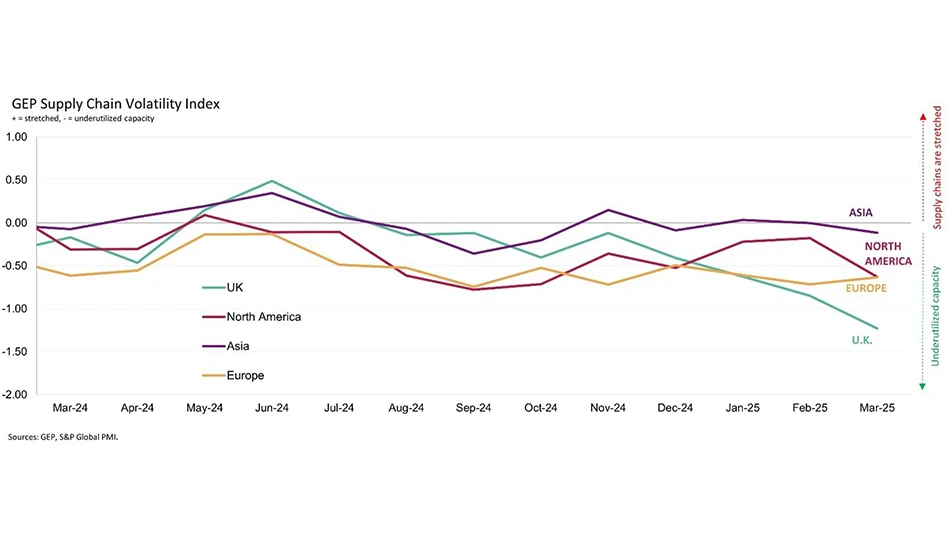

- Unlocking GenAI's potential: Insights from the Supply Chain Horizons 2025 report

- Celebrating 75 years of innovation at Jorgensen Conveyor and Filtration Solutions

- Free webinar to offer expert advice on optimizing machining operations

- How collaboration between companies can elevate manufacturing

- AI meets innovation: Cambridge's device transforms heart screening

- Mazak and Premier Engineering team up for greater agility in Florida

- Struggling with inventory or supply chain pressures? Find answers in our free webinar

- Free webinar: Advanced manufacturing solutions to support the Navy