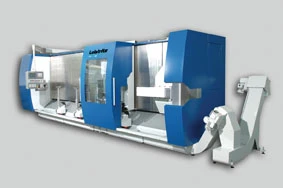

Leistritz has developed a manufacturing solution ideally suited for producing rotors of oil field Down Hole pumps and Power Section Rotors for drill heads by combining a heavy duty, long bed machine with a high powered, high rpm milling head with an innovative hobbing system.

A specially engineered follower rest supports both the raw material in front of the cut and the finished rotor behind the cut to achieve a vibration free operation. Manufacturers can expect to cut a 17-4 PH bar, 2.5 in. with a minor diameter of 1.6 in. at 800 rpm and move across the work at 8 in. / minute in one pass.

The key to the speed of the machine is its new hobbing capability. It allows faster machining times while producing a super fine finish.

The PWM-200 machine is also a fully capable side-milling machine. The milling cutters are supported on both sides, producing no deflection. Every axis of the machine has digital scale feedback and is laser calibrated at the factory for the most accurate positioning available. A rotor can be programmed to run completely unmanned without stopping for the operator to position supports.

Leistritz Corporation Machine Tools Allendale, NJ leistritzcorp.com Booth #B-6729

Explore the July August 2006 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Kistler offers service for piezoelectric force sensors and measuring chains

- Creaform’s Pro version of Scan-to-CAD Application Module

- Humanoid robots to become the next US-China battleground

- Air Turbine Technology’s Air Turbine Spindles 601 Series

- Copper nanoparticles could reduce infection risk of implanted medical device

- Renishaw's TEMPUS technology, RenAM 500 metal AM system

- #52 - Manufacturing Matters - Fall 2024 Aerospace Industry Outlook with Richard Aboulafia

- Tariffs threaten small business growth, increase costs across industries