DMG MORI

Chicago, Illinois – During this year’s Chicago Innovation Days in Hoffman Estates, Illinois, (May 13-16, 2019) DMG MORI will demonstrate the latest trends and innovations in machine tool manufacturing.

The event highlights will be:

- Integrated Digitalization for planning, preparation, production, monitoring, and service

Heading towards the Digital Factory with Open Connectivity – The trend towards industrial digitization is fundamentally altering the framework conditions for metal cutting production technology. DMG MORI's machines have been offering digitization solutions since 2013 with the CELOS app-based control and user interface. And, the company has been expanding the range of solutions it offers to create an open ecosystem for the digital factory. DMG MORI is increasing its portfolio of CELOS services with intelligent software solutions and connective hardware.

- Highly dynamic production machine

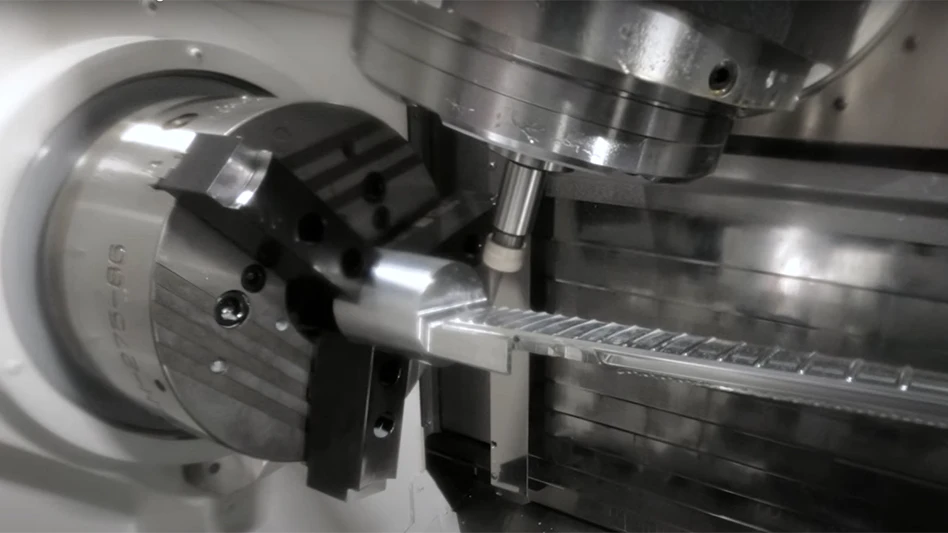

The DMP 70 stands for maximum productivity on the smallest space; with a footprint of just 46.28ft² it is 10% smaller than its predecessor the MILLTAP 700. This compact production machine is for applications in medical technology, job shops, as well as the aerospace sector and other demanding industries. Travel paths of 27" x 16" x 15" and the optional integrated swivel/rotary table enable 5-axis simultaneous machining of a wide range of components making the DMP 70 the ideal addition to any shop floor. Automation solutions such as the workpiece handling WH 3 Cell which can be connected from the right, left, or front of the DMP 70, will be presented at Innovation Days. - Automation Solutions for competitive manufacturing

More value creation through integral automation solutions – Automated machines are crucial components of a digital factory and therefore an integral part of intelligent and networked production. DMG MORI will present automation solutions for machines produced locally in Davis, California.

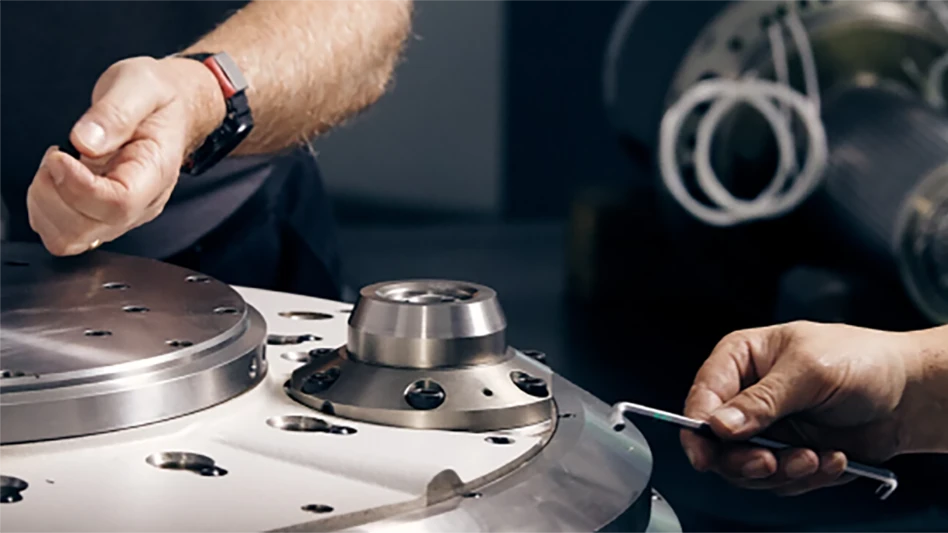

- Additive Manufacturing (AM) with four process chains in the powder bed and with the powder nozzle. Bundled competence at the AM Excellence Center – DMG MORI has five AM Excellence Centers (AMEC) worldwide, including one in Chicago, where engineers design AM solutions involving powder bed and powder nozzle methods.

Additionally, the company will present Technology Excellence in medical, aerospace, die & mold, and automotive; a special focus on the machine tool manufacturer’s 35-year history in 5-axis machining; and two U.S. premieres – the ALX 2000 turning center and the DMP 70 vertical machining center (VMC).

Latest from Today's Medical Developments

- CCAI Finishing Education Foundation’s 2025 National Scholarship Program

- Moticont’s next linear servo motor in the GVCM-032 series

- Walter USA unveils new state-of-the-art campus

- Fixtureworks’ manual-style snap clamps

- Cutting Tool Market Report shows orders up from Sept. 2024

- Mahr’s expanded Precimar SM 60 length measurement family

- Prosthetic material could reduce infections from intravenous catheters

- The Okuma GENOS L3000-e MYW Brings Versatility to the Table