DELCAM WILL DEMONSTRATE THE LATEST VERSIONS of its milling software packages, PowerMILL and FeatureCAM during the Great Lakes show in Grand Rapids, MI, September 18 - 20. These two programs give Delcam the unrivalled ability to provide solutions to companies looking for a programming system for Mills, Mill/Turns, Lathes or Wire EDM. Both FeatureCAM 2008 and PowerMILL 8.0 will focus on options for 5-axis machining.

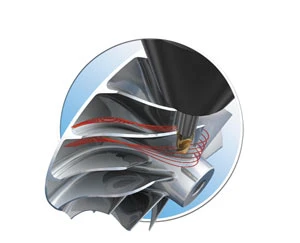

The most significant of the new 5-axis options in Delcam PowerMILL (booth #632) is a powerful tool-axis editing function that allows the user to select any region of a toolpath and redefine the tool-axis vectors within that region. This ability will allow users to optimize cutting conditions, in particular to give faster machining, and to avoid any sudden machine tool movements that could result in a poor surface finish. New automated functionality has also been added for much faster programming of the 5-axis machining of blisks, blades and impellers. Swarf machining has been improved by the addition of an option that forces the toolpaths to follow the surface internal lines where possible. This approach can be used to give smoother motion of the machine tool and more precise control of the cutting conditions. Improvements in simulation and verification include the ability to rotate the ViewMILL machining model both during and after the simulation. In addition, the user interface has been streamlined so that both cutting tool simulation and machine tool verification can be controlled from a single toolbar.

Five-axis simultaneous milling capability is now available in Delcam FeatureCAM (booth #613) for the first time, offering a variety of methods for controlling the tool axis. The user will be able to set a specific lead and/or lean angle. This can be done either to access areas unable to be reached with 3-axis machining or to give better cutting conditions. Alternatively, the tool angle can be set in an orientation either to or from a point, or to or from a line. Many 3- axis toolpaths generated in FeatureCAM will be able to be converted to a 5-axis equivalent by using automatic collision avoidance to change the tool axis. The software will automatically tilt the cutter away from the obstacle by the specified tolerance and then return the cutting angle to the value set for the overall toolpath once the obstacle has been cleared. Various choices will be available to control the direction in which the tool is tilted. Other new options will include 5-axis trimming and swarf machining. Five-axis drilling will also be supported. This new functionality, coupled with the advanced feature recognition in FeatureCAM, will make it possible to create drilling programs in seconds even for multiple hole types and sizes. The new functionality for turning will allow a closed or open curve to be used to define the stock during toolpath calculation, so for example, when machining performs (like castings or parts that have already been rough machined) the stock curve will clip the toolpaths to it, so no toolpaths are generated outside this boundary. This will result in a dramatic reduction in cutting time and minimal air cutting.

FeatureCAM 2008 also features numerous smaller enhancements and speed-ups, plus new and updated post-processors, in particular for turnmill equipment, including the Mazak Integrex, Daewoo Puma and Nakamura- Tome machines.

Explore the September 2007 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- HERMES AWARD 2025 – Jury nominates three tech innovations

- Vision Engineering’s EVO Cam HALO

- How to Reduce First Article Inspection Creation Time by 70% to 90% with DISCUS Software

- FANUC America launches new robot tutorial website for all

- Murata Machinery USA’s MT1065EX twin-spindle, CNC turning center

- #40 - Lunch & Learn with Fagor Automation

- Kistler offers service for piezoelectric force sensors and measuring chains

- Creaform’s Pro version of Scan-to-CAD Application Module