Confluent Medical

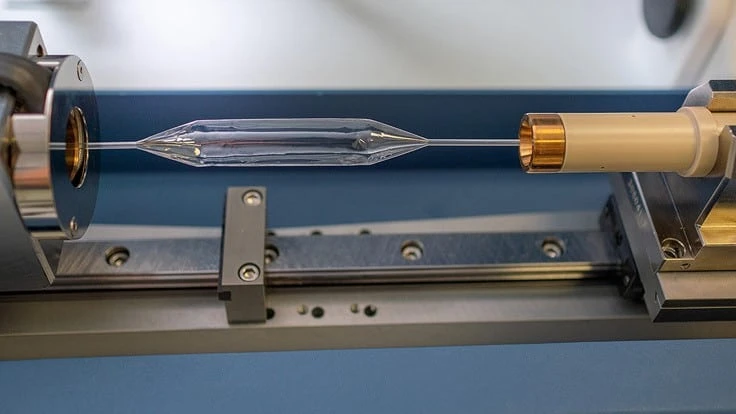

Confluent Medical Technologies, a

global leader in contract manufacturing of specialized medical devices, has

opened its new Complex Catheter Design and Development Center in Austin, Texas.

The state-of-the-art, rapid-prototyping, development and pilot facility greatly expands

Confluent’s ability to provide customers with electrophysiology and

neurovascular catheters, as well as complex delivery systems for structural

heart and vascular applications.

The

Austin Catheter Development Center will support customers from initial design

to rapid-prototyping, regulatory support and through initial pilot builds for

clinical trials. For high-volume production, the Austin facility works closely

with Confluent’s manufacturing center in Costa Rica.

“We’re

extremely excited about our new Austin Catheter Development Center,” says Confluent

CEO and President Dean Schauer. “It greatly expands our capability to develop

new, ready-for-production catheter designs and solidifies our position as the

industry leader in providing fully integrated solutions to medical device

customers.”

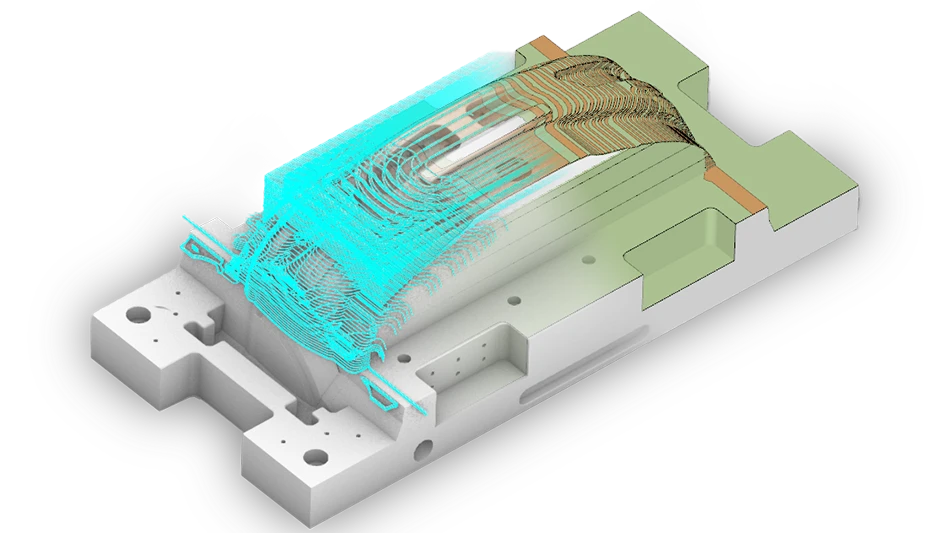

Leveraging

20-plus years of catheter development and manufacturing experience, Confluent

offers a wide range of in-house catheter designs, from catheter components and

balloon catheters to articulating devices and complex delivery systems.

Processes include complex braided or coil-reinforced shafts, laser welding,

over molding, balloon blowing, RF tip forming, robotic adhesives, multi-lumen

extrusions, and thermal bonding.

Confluent

partners with customers to reach product design freeze while planning for

production. The company’s advanced design and development system ensures

products are ready for manufacturing. While production processes are piloted at

the new Austin facility, duplicate equipment at Confluent’s manufacturing

center in Costa Rica ensures a smooth transition to high-volume production.

Get curated news on YOUR industry.

Enter your email to receive our newsletters.Latest from Today's Medical Developments

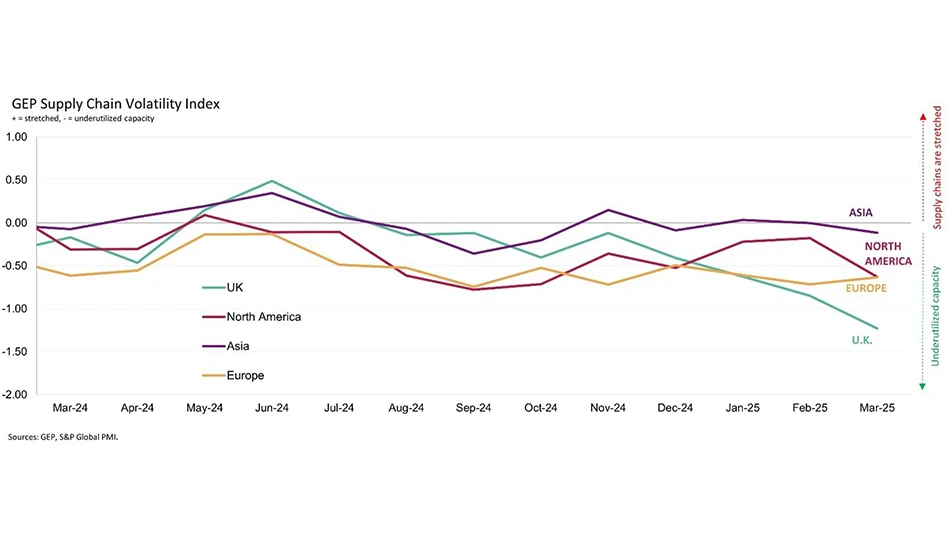

- Unlocking GenAI's potential: Insights from the Supply Chain Horizons 2025 report

- Celebrating 75 years of innovation at Jorgensen Conveyor and Filtration Solutions

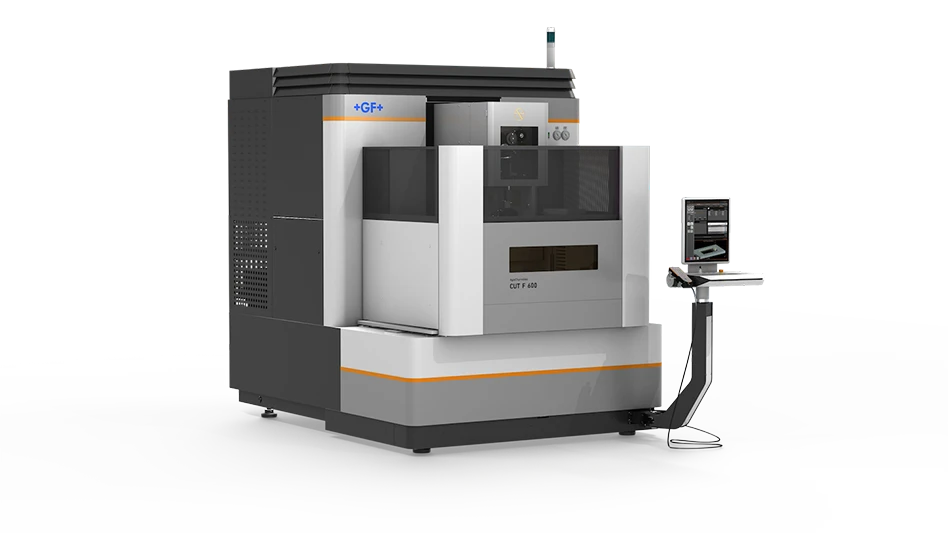

- Free webinar to offer expert advice on optimizing machining operations

- How collaboration between companies can elevate manufacturing

- AI meets innovation: Cambridge's device transforms heart screening

- Mazak and Premier Engineering team up for greater agility in Florida

- Struggling with inventory or supply chain pressures? Find answers in our free webinar

- Free webinar: Advanced manufacturing solutions to support the Navy