When step motors are used in medical related applications, more than likely it is because of their superior accuracy, small size or relatively low cost. In the following case, a step motor was originally designed into a pill dispensing machine because of its high accuracy. Precise movements of the motor's shaft were needed in order to maintain the high efficiency of the dispenser.

The step motor, along with a stand alone driver and stand alone controller, were to be attached to a rack and pinion setup and then ultimately used in the pill dispensing system. Although both the step motor and its related parts were performing well, some problems arose because of the amount of space that the driver and controller demanded. The design of the overall system called for the most efficient use of space; the driver and controller units, coupled with their cabling, made it hard to adhere to this standard.

Since both a drive and a control are necessary components in enabling a step motor to function, they are not easily replaceable. Redesigning the entire system was not an option, so an alternate solution needed to be found.

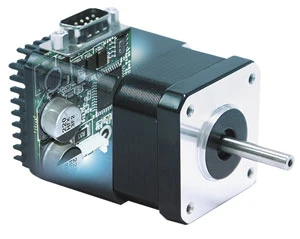

After looking at various alternatives, the developer of the pill dispenser contacted Lin Engineering, step motor manufacturer. Lin Engineering studied the application's requirements and recommended the use of its SilverPak series. The SilverPak series consists of a step motor that's integrated with a driver and controller.

With both the driver and controller mounted on the back of the motor, the overall size of the package is greatly reduced. This design also negates the use of multiple cables and simplifies the wiring process. Since Lin Engineering offers these motors in both NEMA 17 and NEMA 23 frame sizes, they were able to match the specifications of the existing design. After the SilverPak motors were implemented into the machine, they proved to be smaller than the original design and there was no drop off in performance.

Furthermore, the pinion portion of this rack & pinion application required that a set screw be used to place the pinion onto the shaft of the motor. Lin Engineering was able to provide a flat on the shaft in order to create a better surface for the set screw. The pinion was easily mounted and provided a stable surface for the rack.

With the new setup, space was saved and a larger tray was placed onto the rack portion of the system. When the step motor rotated the pinion, the rack began moving linearly, allowing a dispensing of more pills per tray, increasing productivity while still maintaining the performance at a low cost.

Explore the August 2007 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- LK Metrology acquires Nikon Metrology’s laser scanning and Focus software assets

- Flexxbotics’ robot compatibility with LMI Technologies 3D scanning, inspection products

- IMTS 2024 Booth Tour: Behringer Saws

- UNITED GRINDING Group to acquire GF Machining Solutions

- Mitutoyo America’s Metlogix M3 with the Quick Image Vision System

- IMTS 2024 Booth Tour: Belmont Equipment & Technologies

- Krell Technologies launches Photonics Outreach Program

- Hurco’s TM8MYi lathe