At the heart of any manufacturing facility are the machine tools that enable the designers, engineers and machinists to make component parts and finished products. For those applications that use bar stock as raw material, the device that feeds these bars into the machine tool becomes the lifeblood of the process. In fact, manufacturers who make precision medical parts such as implants, surgical instruments, transcatheter devices, orthopedic screws, defibrillator components and much more, recognize the value that bar feeders bring to their operations.

What has been found is that, whether it is small batches of parts or high-volume production, a bar feeder can reduce the amount of time an operator spends on a machining cycle while allowing the machine tool to operate at maximum spindle speeds. As a result, there are fewer labor hours and less machine time invested in each part they make. These cost reductions add up quickly, especially when the equipment can run unattended during lunch hours, operator breaks, and even overnight and on weekends. Equally important, bar feeders help the CNC machines maintain critical tolerances by eliminating bar stock vibrations within the cutting zone.

Bar feeders make this possible because they not only load the bar stock into the machine tool - quickly and accurately - they also support the bars while they are turning at all ranges of speed. Since bar stock is rarely perfectly straight, as it rotates it can create a whipping effect that impacts the accuracy of the cut and creates a serious safety hazard to the machine tool and the operator. Without a bar feeder - or with an inadequate one - the machine operator must reduce the machine's spindle speed, resulting in added time and labor to the cost of making parts.

Bar Feeder Basics

Depending on the specific applications, users can choose from a variety of bar feed types. LNS, for example, makes bar feeders for sliding, fixed and traveling headstock machines.

The product line covers bar stock diameters from 0.039" - 4-3/4". The key, of course, is to precisely define the requirements and then match the bar feeding system to both the machine tool involved and the nature of the process.

The hydrodynamic principle uses the hydrodynamic force of oil to keep the bar centered as it picks up speed, ensuring a smooth and vibration-free operation.

Bar feeders come in three basic configurations:

- Manual load units are the simplest types - they automatically advance one 12ft bar into the machine tool and use an end-of-bar signal to alert the operator when it is time to load the next bar. These bar feeders are adequate for some one-offs and other short runs, or for complex applications with long cycle times. They are not recommended for high-volume runs.

- Automatic bar feeders for 12ft long bars hold multiple bars in a magazine. The number of bars held by the magazine depends on the bar stock diameter. As a bar is used up, the feeder automatically loads the next bar. This enables one operator to run multiple machine tools, and allows for both unattended operation and high-volume production while holding critical tolerances.

- Similarly, automatic, magazinetype short loaders automatically feed bars that have been cut to the length of the headstock. Short loaders do not require guide channels or oil to support the bar stock, require little operator involvement for diameter changeovers, and take up less floor space.

The goal for all three types of bar feeders is to load the bar stock quickly and flawlessly, reduce vibration as the bar turns, and optimize the machine tool's spindle speed. Many 12ft manual and automatic bar feeders use the hydrodynamic principle developed by LNS. This approach involves injecting oil into the guiding channels. As the rotating bar picks up speed, the hydrodynamic force of the oil keeps the bar centered to ensure a smooth and vibration-free operation. Other 12ft models rely on another LNS developed concept - hydrostatic operation - that uses a self-opening bearing block and a film of pressurized oil to accomplish the same result.

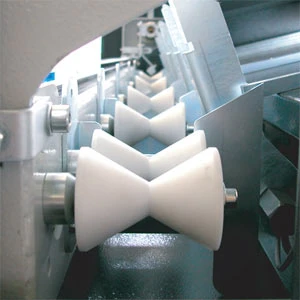

Short-load bar feeders virtually eliminate vibration problems because the machine spindle guides the bar stock and they use smaller bar lengths. However, the bar feeder must still provide smooth loading action and provide proper support. This is accomplished in part, by the use of servo drives, absolute encoders and hard rollers.

Flexibility

For manufacturers serving the medical community, the ability to run a wide variety of parts opens up many more opportunities for work. When selecting a bar feeder, it is critical to consider how quickly and easily change over from one diameter bar stock to another can be accomplished. Some machines require a lengthy process that involves removing and replacing critical components, complicated re-programming of the control, and making several manual adjustments.

Going through all of these procedures can add substantial time and labor costs to the change-over process. On the other hand, more advanced bar feeders include a host of automatic features that reduce change-over times to a few minutes or less. LNS Quick Load Servo models, for example, provide 15-second change-overs within the pusher range.

Manufacturers of medical products like these have learned that a bar feeder can reduce machining cycle times, allowing the machine tool to operate at maximum spindle speeds.

New Challenges

As machine tools continue to evolve they have become more capable of holding tighter tolerances, while significantly increasing spindle speeds and traveling headstock feedrates. These advances can improve manufacturing productivity significantly if the machine tools and bar feeders are properly matched. Many bar feeders simply cannot keep up with the increased spindle speed and feedrates of these newer machines. The challenge to the bar feeder is to repeatedly load bar stock efficiently while preventing the machine tool, bar stock and workpiece from being damaged due to missloading or a turret crash. This is especially true when producing small diameter parts or long shafts, maintaining higher tolerances, or cutting special materials such as titanium.

Unfortunately, many attempts to deal with this issue have fallen short or created additional problems. However, by working with machine tool manufacturers, LNS developed a unique solution by creating a system that maintains constant, dynamic bar stock position control throughout the machining cycle.

The patented "3-S" Intelligent Synchronization system links a controller, strategically placed sensors, and servo-driven motors that are directly connected to the headstock. The system eliminates transmission delay and programmed dwells, reducing cycle time. It actually anticipates headstock motion by continuously monitoring sliding headstock and bar feeding movements. The result is precise synchronization of the movements of the pusher and the lathe headstock, virtually eliminating bar stock misalignment and allowing the machine tool to operate safely and at peak efficiency.

The latest opportunity for bar feeders to improve productivity is through enhanced communications with CNC turning machines or multi-station machining centers. LNS' Advanced Ethernet Interface (AEI) addresses the need for this enhanced communication.

Although initially the idea was to reduce the cost of the interface and make change-overs quicker and easier, a number of other opportunities to improve productivity soon surfaced.

Working with leading CNC machine OEMs, and using input from many endusers, the AEI is evolving into a multi-faceted communication system.

For example, it has the ability to efficiently complete an infinite mix of long or short production runs, a complex family of parts, and even a variety of unrelated parts with little or no operator intervention.

Bar feeders support bar stock as it rotates to eliminate vibration, improve accuracies and enhance machine tool performance.

AEI operates like this: The operator programs the machine tool for a series of runs. As each job is ready to begin, the machine's controller selects the correct tooling from an Automatic Tool Changer (ATC). The AEI then informs the LNS bar feed of the new job parameters. The bar feed automatically performs adjustments for such factors as bar diameter, part length and pusher travel to accommodate the job. All of these adjustments are automatically performed on select bar feed models. As a result, the machine tool can move seamlessly from one job to another without operator assistance.

In today's highly competitive, global marketplace, success is often measured by a manufacturer's ability to make parts faster, cheaper and better.

For those engaged in manufacturing medical parts, having the right equipment feeding bar stock into the machine tools can greatly enhance both the productivity and the quality of products.

LNS America Inc.

Cincinnati, OH

lns-america.com

Explore the October 2009 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Robot orders accelerate in Q3

- Pro Shrink TubeChiller makes shrink-fit tool holding safer, easier

- Revolutionizing biocompatibility: The role of amnion in next-generation medical devices

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.