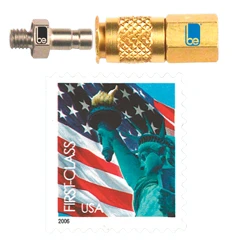

It is the world's smallest M3 threaded quick disconnect. Customers find that it is an excellent choice when small package size, leak-tightness, durability and light weights are required.

This M3 metric threaded quick disconnect adds to Beswick's growing family of single and multiple line quick disconnects with 10-32 UNF and 1/8 NPT threads as well as tubing barbs. The Beswick M3 metric threaded quick disconnect is comprised of brass or stainless steel internal end and a stainless steel external end. The entire assembly weighs only 3.4g. The internal end is designed with an automatic shutoff valve and an M3 internal thread. This end is only about 16.7mm long and has a 6mm hexagonal body. The external end is designed with M3 external thread and includes a captured O- ring seal. The O-ring seal provides a leak-tight connection. The external end is only about 11mm long and has a 5mm hexagonal body. Buna-N is the standard O-ring material. Other O-ring materials are available to resist extreme temperatures and corrosive gases and liquids.

Every quick disconnect is inspected and tested to verify that it is leak-tight. The performance and ultra-miniature size of this quick disconnect assembly will make it easier for customers to miniaturize their products. Standard applications for Beswick products are in instrumentation devices, portable fuel cells, UAV aircraft, medical equipment, laboratory equipment, packaging machinery, semiconductor manufacturing equipment, toxic gas detection, industrial robots, homeland defense devices, ink jet print engines and pharmaceutical machinery.

Explore the January February 2007 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- The role of robotics in precision medical device manufacturing

- Swiss Steel Group’s UGIMA-X machinable stainless-steel sets

- #51 - Manufacturing Matters - The Impact of M&A in MedTech 2024

- Visual Components: 25 years of simulation and programming software innovation

- Zimmer Biomet announces definitive agreement to Acquire Paragon 28

- Discover an innovative technology for EMI/ESD/TVS suppression

- Teleflex to acquire BIOTRONIK’s Vascular Intervention business

- Innovation at Global Industrie 2025