Photo courtesy of PVA TePla America

Plasma treatment offers cleaning and decontamination, surface conditioning, and adhesion promotion, but specifying and integrating equipment to automate the process can be daunting. With so many applications and part sizes to be processed, standard off-the-shelf vacuum chamber solutions rarely suffice. With plasma treatment increasingly integrated into existing production systems, replacing manual operations with automated production becomes more important.

Though automated plasma treatment can be challenging, manufacturers typically don’t need custom tools because plasma equipment providers can semi-customize existing tools and technology to accommodate new or non-standard parts. This includes providing the necessary robotics for high throughput and automated loading and processing.

“At least once a week we talk with customers about some sort of customization of our existing standardized systems,” says Walt Roloson, R&D engineering manager at PVA TePla, a designer and manufacturer of plasma systems. “I would estimate 60% of the equipment we deliver has gone through some degree of customization.”

Recently, IMA Automation Medtech, a Swiss company that designs turnkey automated assembly lines for medical devices, requested a system that would automate an existing manually-loaded plasma treatment system.

The small vacuum plasma chamber would treat several pallets of 4cm to 5cm items in an automated batch process, a critical surface activation step prior to a coating application. Each 12" x 12" aluminum pallet held 300 items, and the system’s users needed a processing time of less than 8 minutes from loading to unloading.

The system was part of a larger IMA Automation Medtech manufacturing cell that included a flex-feed device for loading packaged parts into the pallets, plasma treatment, coating, curing, and final coating/curing step.

IMA Automation Medtech also wanted a plasma equipment provider that was willing to pre-test the tool to validate performance prior to delivery.

“We wanted the equipment supplier to test parts to give us confidence purchasing the system,” says Ruben De Araujo, a process engineer for IMA Automation Medtech. “We were also looking for a company that was established enough to support the customer in Europe, because the line will be installed there.”

The initial specifications sent by IMA Automation Medtech to PVA TePla were several pages long, complete with CAD drawings. The one-off unit had many custom elements such as a conveyorized track that transported the pallets in and out of the vacuum chamber.

“We had never built anything like it, so it would have been a completely custom solution if we had to match it,” Roloson says. “However, the general concept of automatically loading and unloading pallets with pick-and-place robots and treating parts in batches, we have done many times.”

PVA TePla proposed a semi-customized version of one of its smaller production-level vacuum chamber tools, Roloson explains, because, “it could process pallets in batches, and we already had a kit to add robotics to it.”

Customizing a standard tool saves time and money, whereas a fully customized system could require as much as 400 to 450 hours of engineering.

Software customization

Roloson says the most significant change from IMA Automation Medtech’s request was altering communication and control software.

As a company supplying automated systems to the medical, pharmaceutical, and food industries, IMA Automation Medtech must comply with Title 21 CFR Part 11 regulations established by the U.S. Food and Drug Administration (FDA) for electronic records. This requires companies to implement controls, including audits, system validations, audit trails, electronic signatures, and documentation for software and systems involved in processing electronic data.

With this in mind, IMA Automation Medtech decided not to send information through standard RS-232 or Ethernet connections and instead opted to use a programmable logic controller (PLC)-based communications and control system, both for security and to work with the other component parts of the automated line.

“Regarding the software interface to the rest of our machine, we decided the PVA TePla system should communicate with our PLCs in a way that we were sure that the data that is collected is secure,” De Araujo says.

Although PVA TePla’s standard systems are designed to facilitate Part 11 compliance, standard models are PC-based. To meet IMA Automation Medtech’s requirement, the company’s in-house computer software and control engineer altered the system to communicate via PLC with digital output signals designed to read as binary code.

The PLCs send treatment recipes and process the answer values as well as control the automated loading and chamber door opening elements. Internet communication is only used for sending batch processing data to a SQL server.

Hardware modifications

Some hardware modifications were required as well. PVA TePla’s vacuum ports are typically located at the back of each unit. However, to match the existing system, IMA Automation Medtech wanted the vacuum ports at the bottom of the chamber.

The port placement affected the flow of ionized gas over the parts, and in this case the customer was concerned about the treatment on the inner side of each part, something occasionally difficult with the original equipment. Relocating the vacuum port to the bottom of the chamber improved surface conditioning in angle goniometry tests.

“We did tests on the [processed part] samples they provided, and the contact angle was excellent,” De Araujo says. “It was better than what the customer was getting before.”

Because the system is in a cleanroom, IMA Automation Medtech required a special air-cooled dry vacuum pump to eliminate the need for water pipes to cool it down. A slow vent design prevents heat in the chamber from damaging sensitive parts. Slowing the venting process ensures the insertion of air into the system at atmospheric pressure is slowed to reduce the heating effect.

Preparing for the future

For customers who may not be ready to automate, plasma equipment tools can be configured to keep options open for future upgrades as production increases.

“Some customers purchase a manual batch tool with the idea that at some point, they are going to have to automate,” Roloson says. “If they have a tool with our standard software, we can add a robotic interface and modify it so there is an automatic door and atmosphere switch, and it can become fully automated.”

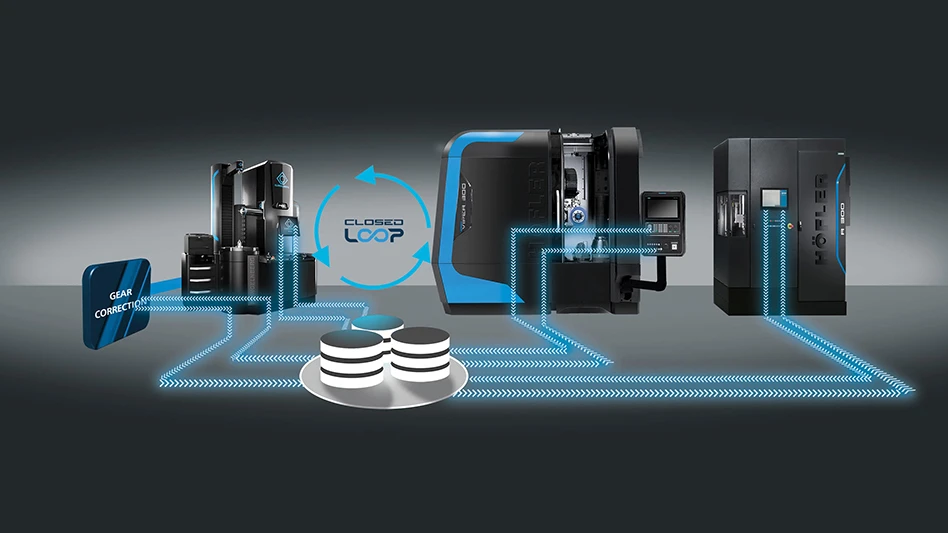

If production levels increase to higher levels, a high-throughput system can be designed by creating a cluster of plasma tools served by a single universal robot in the center.

“The elegance of the automated plasma treatment solutions available lets a new customer leverage existing technology and know-how, as opposed to having to pay to create something that is entirely new,” Roloson concludes.

IMA Automation Medtech

https://ima.it

PVA TePla America

http://www.pvateplaamerica.com

Explore the March 2019 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- MedTech Innovator welcomes five new industry partners

- First Article Inspection for quality control

- The manufacturing resurgence is here – are you ready?

- Workholding solutions for your business

- ZOLLER events will showcase the company’s cutting-edge innovations

- THINBIT’s MINI GROOVE ‘N TURN Acme threading inserts

- CMMC Roll Out: When Do I Need to Comply? webinar

- Metabolic research uses Siemens gas analyzers to deliver results with 99.9999% resolutions