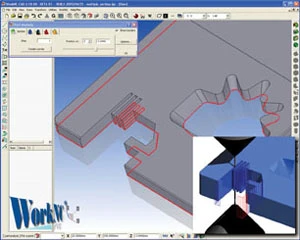

Sescoi will demonstrate the improvements that have been made to their WorkNC recognition software.

The automatic hole data detection has been optimized to provide better recognition. Inside WorkNC, customizable tolerance settings allow the software to identify holes that are out of round, partially defined, or coaxially positioned, so that they can be drilled in the same view, as well as those positioned at the same point to avoid double drilling. The more information that is available about each hole, the less additional data the programmer has to supply to fully define each machining operation. Where the machine tool is capable of moving in more than 3-axes, WorkNC will also find holes in other planes, automatically setting the parameters and views necessary to cut them.

Sescoi, Inc. Southfield, MI sescoi.com Booth #D-3015

Explore the July August 2006 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Kistler offers service for piezoelectric force sensors and measuring chains

- Creaform’s Pro version of Scan-to-CAD Application Module

- Humanoid robots to become the next US-China battleground

- Air Turbine Technology’s Air Turbine Spindles 601 Series

- Copper nanoparticles could reduce infection risk of implanted medical device

- Renishaw's TEMPUS technology, RenAM 500 metal AM system

- #52 - Manufacturing Matters - Fall 2024 Aerospace Industry Outlook with Richard Aboulafia

- Tariffs threaten small business growth, increase costs across industries