Start with some steel tubing, sheet metal, and bar stock. Cut the steel. Weld it together. Machine it. Deburr it. Grind the joints. Haul it into the spray booth for priming and painting and wait a day or two for it to dry. Then, mount the hardware.

Timeconsuming, cumbersome, not readily reused welded steel is going the way of the stone tablet for a growing list of structural designs, as it is quickly being replaced by aluminum structural framing. Aluminum structural framing is no longer just for common factory structures like machine bases and workstations. Now, it is also finding its way into new, innovative applications in the medical industry.

Previously, medical uses of aluminum structural framing were somewhat unusual, but more and more companies are developing new ways to incorporate this modular, flexible, reusable structural component. In fact, by using aluminum framing, almost any structure can be assembled without special tools or skills and in significantly less time.

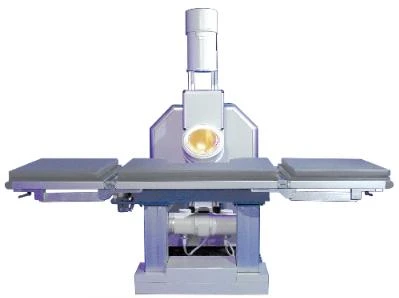

ESWL Products, Inc.s Lithowave lithotripter, for example, is a special piece of equipment specifically designed for noninvasive treatment of kidney stones, and it is the latest design our company has developed using aluminum structural framing from Bosch Rexroths Linear Motion and Assembly Technologies division.

Breaking Up Is Hard to Do

The extracorporeal shock wave lithotripsy performed on the Lithowave lithotripter is a nonsurgical procedure in which shock waves are produced by the machine outside the body and focused on kidney stones inside the body. The shock waves are used to break up kidney stones into smaller pieces, thus allowing them to pass through the bodys urinary system. (Interestingly, kidney stones are more common in arid and tropical climates because perspiration, as a method of cooling the body, limits the flow of urine in these climates. As a result, the concentration of minerals that produce kidney stones is much higher in people who live in these areas.)

To generate a shock wave, the Lithowave lithotripter employs spark gap technology, which harnesses the energy released during an electrical discharge created between two electrodes submerged in water. When the reflected shock wave is positioned on the treatment area, such as the kidney stone inside the body, the repeated impact of the shock waves on the stone, at various energy levels, causes its disintegration.

The Lithowave is a thirdgeneration extracorporeal shock wave lithotripter that offers clinicians a proven electrohydraulic spark gap energy source coupled with a fluoroscopic localization system and a multifunctional operating table. Distinct features of the patented Lithowave design include the positioning of both the treatment unit and the target localizing fluoroscopy on two frames mounted on one shaft and revolving around the same axis. This centerbased design offers significant advantages over traditional designs.

The system control console is the focus of control and monitoring of the system. It provides the operator with centralized means for controlling the treatment table, the lithotripsy systems, radiology, and imaging, and it is usually located in a separate control room or minimally behind an Xray shielding partition. Positioning of the control console is very easy since it is completely mobile.

A touch screen interface and a fluoroscopy control panel are part of the control console. Additional controls and indicators are located on the side of the lithotripter enclosure. These switches are divided into three clusters to control main power, treatment unit positioning, and a water system.

After the stone is localized, the operator must adjust the position of the treatment unit and establish proper contact between the patients skin and the membrane of the treatment unit. This part of the procedure is carried out using the controls located on the control panel on the side of the main enclosure. The rest of the treatment is conducted from the control console. The flexible positioning of the table and the radiology apparatus, unparalleled access to the patient, and easily accessible controls all simplify the endourological procedures for treating kidney stones.

Explore the January 2005 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Teleflex sells acute care and urology businesses for $2.03 billion

- HANNOVER MESSE: Where research and manufacturing meet

- What’s next for the design and manufacturing industry in 2026?

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Robot orders accelerate in Q3