Junkosha, a provider of peelable heat shrink tubing (PHST) technology, offers ultra-small, high-shrink ratio PHST, delivering a solution for accessing to the most exacting parts of the vasculature with minimal impact on the patient. Suitable as tubing for laminating jacket coating in tiny guide wires, 0.011" and 0.014", PHST has a recovered ID as low as 0.009". Miniature guide wires navigate vessels to reach a lesion or vessel segment within the brain or heart. The high-shrink ratio PHST (2:1) supports processes where tapered microcatheter shafts are used or where tolerance take-up is an issue.

“Our aim is to answer customers’ unmet needs through technology innovation. As a part of this, we are being asked for solutions that take small to the next level,” says Joe Rowan, president and CEO of USA and Europe, Junkosha.

Polycarbonate for better performing IV connectors

Makrolon Rx3440, a medical polycarbonate from Covestro LLC, offers durability and chemical resistance to prevent cracking for safer delivery of oncology drugs, and demonstrates retention of stress to provide more reliable IV connections.

Advantages include:- Biocompatible to ISO 10993-1, USP Class IV standards

- Greater structural integrity for thin-walled designs

- Toughness to resist mishandling

- Dimensional stability in shipping, storage

Piezo-mechanic nanopositioning motion systems

Products covered range from low-cost OEM-type flexure actuators to 6-axis integrated nanopositioning systems, ultra-fast laser steering systems, and photonics alignment systems. Along with the piezo mechanic systems, digital controllers and sub-nanometer precise position sensors are part of the solutions available.

Rotary ball spline, precise robotic movement

Explore the March 2018 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Minalex celebrates 60 years of excellence in miniature aluminum extrusions

- Tormach’s Chip Conveyor Kit for the 1500MX CNC Mill

- #39 - Lunch & Learn Podcast with EMUGE-FRANKEN USA and Okuma America

- Significant expansion for Intricon

- REGO-FIX’s powRgrip toolholding system

- Birk Manufacturing achieves ISO 13485 recertification

- AdvaMed’s Medical Innovation Agenda for the 119th Congress

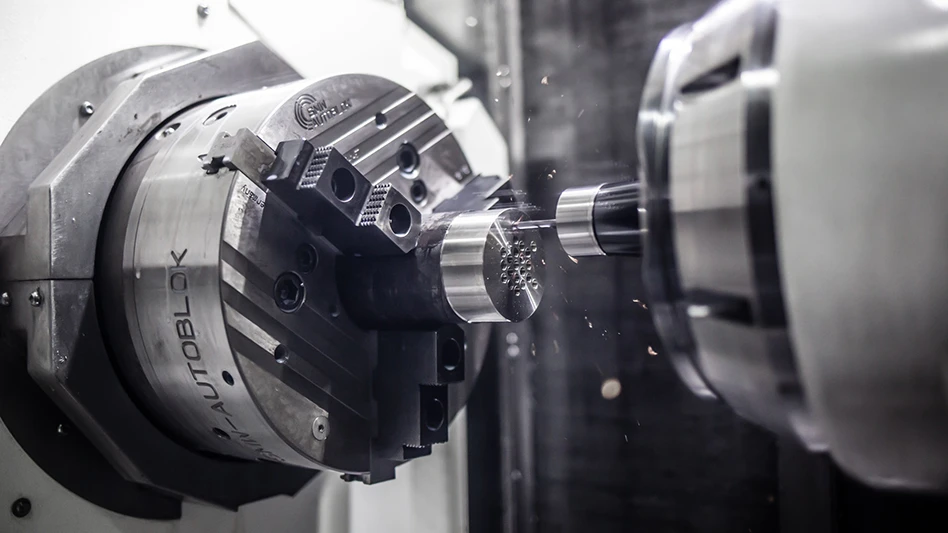

- SW North America's BA 322i twin-spindle CNC