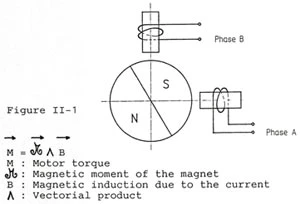

To understand how these motors operate, consider figure II-1.

Stepper Motors have gained tremendous success in recent years, thanks in part to the progress of the semiconductor industry. Stepper motors' advantage of speed and position control without feedback is becoming increasingly attractive to industries sensitive to cost. There are several designs that can be used for stepper motors, including rare earth permanent magnets. These magnets offer designers opportunities to obtain performance attributes that rival brushless DC technology.

SALIENT DIFFERENCES BETWEEN A TRADITIONAL

BRUSHLESS DC (BLDC) AND A STEPPER MOTOR:

Both BLDC and stepper motors have identical principles

to that of a DC motor, having its magnet moving instead of the copper.

Stepper motors can be divided into two basic groups. The first group works without permanent magnets, while the second group uses permanent magnets located in the rotor. Variable reluctance motors form the first group, and the original permanent magnet motor, the hybrid motor and the disc magnet motor form the second group.

THE CONVENTIONAL PERMANENT MAGNET STEPPER MOTOR (PM)

The rotor of this motor consists of a cylindrical permanent

magnet that is radially magnetized. The basic design

clearly shows that the directions in which the rotor is going

to move will depend on the magnetic polarity of the stator

poles, hence in the direction of the phase currents.

2-phase permanent magnet stepper motor.

This 2-phase, permanent magnet stepper motor has a rotor with three pairs of poles. It will make 12 steps per revolution, 2 phases x 6 poles, and will have a step angle of 30°. There are no teeth on the rotor.

The majority of conventional permanent magnet steppers are either of the 2-phase bipolar or the 4-phase unipolar type. With bipolar, the phase current changes direction every other step. In unipolar steppers, the phase current is on or off, but doesn't change direction. If figure III-2 (pg. 81) is considered a 2-phase motor, phase one consists of coils A and A1 and phase two of coils B and B1. If it is a 4-phase, unipolar motor, then coil A is phase one and coil B is phase two, coil A1 is phase three and coil B1 is phase four. In that case, coil A and A1 could be combined in one bifilar winding, and so would coils B and B1.

The principle of combining VR and PM motors.

THE HYBRID STEPPER MOTOR

As indicated by its name, the rotor of

a hybrid motor has both a permanent

magnet and teeth. These will physically

modify the airgap as the rotors move;

therefore, the inductance of the phase

winding changes with rotor position.

Example of a disc magnet (DM) motor.

THE DISC MAGNET TECHNOLOGY

In the '60s, when quartz-controlled

watches appeared on the market, PORTESCAP

developed a new type of stepper

motor used for driving the hands

of these watches. The motor had to be

very small and very efficient. This is the

time that permanent magnets made of

rare earth elements became available.

Their high magnetic energy made it

possible to magnetize a relatively long

airgap using a magnet that was actually

shorter than the airgap. A considerable research

and development effort resulted in

the single-phase stepper motor with "thin

disc magnet rotors" being used in many

millions of watches, and finally leading to

the "2-phase disc magnet stepper motor"

presented in 1981.

Magnetic circuit.

Looking at the magnetic circuit, one can easily understand that the magnet will have different working points versus its position and versus the flux generated by the winding itself.

When a pole is inside the airgap, the working point of the magnet on the BH curve is very high and the magnetic induction is at its maximum. When a pole is outside of the airgap, the magnet is in the air and the working point is then very low. It means that one needs a magnet very linear in the second quadrant of the BH curve. This is possible with rare earth permanent magnets. Add to this some current in the winding, and you have the working point of the magnet covering a wide area on the BH curve.

Observe that the magnetic and electromagnetic circuits are both optimally designed by having the energy source at the airgap. Most motors, which use iron to guide flux, have iron "teeth". It is the teeth that face the airgap and they are the flux source. The coils are somewhere behind the airgap. Similarly, the permanent magnet poles of the DM motor face the airgaps, they are not buried in the structure, and they do not require any iron pole pieces to direct flux.

Recommended and non-recommended circuits.

The penalties of the non-recommended circuit are losses, lower efficiency and flux leakage. This is because the airgap is the largest reluctance of any magnetic circuit. When flux is forced to cross an airgap, it will look for all alternative paths. If the permanent magnet is at the airgap, the flux will be forced across the gap in a much more concentrated bundle. The same is true for the electromagnetic circuit in that with the coils "at the airgap", the flux is prevented from wandering.

NO HARMONIC DISTORTIONS

The torque-displacement curves of step

motors are supposed to be sinusoids. Any

textbook, handbook and manufacturer

literature will show such sinusoidal curves.

In fact, the curves of all but the DM motor

have harmonic distortions due primarily

to tooth geometry ratios. To further complicate

the matter, the distortion curves

are not constant, meaning that as more

current is applied, the distortion changes

and therefore the distortion may not be

characterized. DM motor curves are undistorted.

Pure sinusoids mean better accuracy

when positioning in the microstepping

mode of operation where sine/cosine

current ratios are used. As positioning current

varies from zero to maximum, linearity

is needed to achieve a consistent torque

constant.

These rare earth permanent magnets are utilized in PORTESCAP disc magnet stepper motors from Danaher Motion so that the motors have all the advantages required for fast incremental motion, such as acceleration and power-rate. Electronic improvements also give new opportunities, as we always have to consider the entire system, not only the motor.

A few years ago, the majority of stepper applications used L/R Unipolar drives. Now, more and more applications require current source drives (PWM). The next step towards a system having better performances would be the combination of stepper and BLDC mode; at low speeds the stepper would work in microstepping mode and at high speeds in BLDC mode.

OVERLAPPING CAPABILITIES

Because of recent changes in cost,

torque, setup and tuning, the line that separates

the choice between steppers and

servomotors is hazier than ever. Design

situations may be further complicated by

the fact that a machine often needs both

types of motors, depending on the type of

axes involved.

Power is usually the first factor considered when making the decision. Usually, with less than 1,000rpm, the choice falls to steppers. Above 3,000rpm, the choice leans more toward servomotors. That is changing, especially in the 1,000rpm range, where both types of motors have overlapping capabilities. When considering horsepower, servomotors in the fractional to 2hp range have the largest overlap with brushed and brushless steppers. Above 2hp, the brushless servomotor is typically favored. Because of steppers' increased torque, these motors can provide extremely accurate, stiff performance at low speeds, without a gearbox or other types of mechanical advantage.

The disc magnet step motor offers a marriage of the permanent magnet motor with the brushless motor. As a result, designers have the advantage to utilize the low inertia to achieve high torque output at higher speeds. Speeds of up to 10,000rpm can be achieved with significantly less torque fall-off than with a hybrid step motor. This combination is well-suited for applications that require quick movement and accurate positioning.

Servomotors are ideally designed to run at high speeds. They can run under precision control at extremely low speeds, even down to 0rpm. However, because of the oversized rotors now used in steppers, these motors can produce more torque for a given frame size than a servomotor at speeds below 1,000rpm, during stall or when holding a load. As speeds increase above 1,000rpm; however, the torque within a step motor begins to fall off. In a servomotor, the torque doesn't start to fall off until speed reaches 2,500rpm to 3,000rpm, or sometimes higher.

Even with the developments in servomotors that broaden their application range, steppers are still around 30% less costly compared with an equivalent servo system. Conversely, steppers can be used in applications that have traditionally been servomotor territory. If an application has predictable loads, for example, a stepper can move them with high repeatability and reliability. If external forces are low, a stepper can save cost over a comparable servo system. High-resolution applications are naturals for steppers, whether the motor runs open-loop or has a built-in feedback device. And constant power applications can be more cost effective with steppers rather than with servomotors.

Explore the March 2007 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Robot orders accelerate in Q3

- Pro Shrink TubeChiller makes shrink-fit tool holding safer, easier

- Revolutionizing biocompatibility: The role of amnion in next-generation medical devices

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.