EOS

1.How is additive manufacturing (AM) used in the medical field?

The majority of AM medical devices are implants, with about 79% being titanium, according to recent FDA analysis. Pioneers are now getting clearance for third or fourth implants. Titanium acetabular cups recently achieved 10-year clinical history.

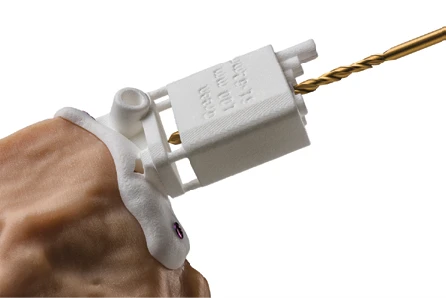

Patient-specific cutting guides made from nylon also have more than 10 years of clinical history. At EOS, we are seeing more orthosis and prosthesis applications due to the ability to print reliable patient-specific devices

As one of the earliest suppliers of additive technology, EOS has gathered a long history of user needs, which we used to develop a new polymer machine, the Integra P400, showcased at RAPID + TCT.

2.Which Integra P 400 features benefit the medical industry?

Customers have been pushing technology providers for faster build times. In response to this, Integra P 400’s novel dual recoating system design can spread preheated powder across the build platform at 0.4m/sec. Preheating decreases the time between layers, traditionally needed to create thermal homogeneity. A new scanning strategy using a 120W CO2 laser and digital galvanometers further decreases layer time, speeding the build process.

Polymer powder bed systems had required warm-up and cool-down time to address thermal warping and part accuracy. The Integra P 400’s laser window enables rapid turnover to increase machine production time. Parts still need to cool to ensure accuracy, but equipment doesn’t sit idle during cooling.

3.What new features in the Integra P 400 support quality control?

The Integra P 400’s built-in monitoring system uses an IR camera to identify cold or hot spots in the build chamber. Consistent temperature is essential for polymer AM, so this monitoring demonstrates that what you expected to build was built – without destructive testing.

In addition, independently adjustable quartz heating in eight zones promotes uniform thermal distribution for homogenized part production. This greatly increases system reliability and reduces scrap.

4.Does the AM process affect biocompatibility?

So far, regulators have cleared devices, not materials. So, it’s a misconception to say a material has FDA clearance or approval. EOS approaches biocompatibility with some initial biocompatibility testing according to ISO 10993. This gives customers an indication that a printed part is biocompatible, but as always, it’s up to the device manufacturer to ensure the final, finished, serialized device is biocompatible. Several customers have device clinical history with our polymer and metal materials, such as PA2200 and PA1101 or our titanium alloys.

5.What is the most common AM implementation challenge you see?

Two challenges are common for device manufacturers new to AM. The first is not taking the manufacturing process into account during design. The design team can not work in a silo from the manufacturing team; it’s critical both teams have input during the design stage for part orientation with respect to critical features, for example.

The second would be adding AM into the quality system. Since AM is new and does not have many standards to reference, many manufacturers see this as a hurdle. Our applied engineering consultant team, Additive Minds, can help customers identify gaps in their quality systems.

Most customers purchase this service with their first production machine.

Our philosophy is to teach the customer what they need to know so then they can apply it to the next product in their pipeline.

FOR MORE INFO:

https://www.eos.info

@EOSNorthAmerica

Linkedin.com/company/EOS

Facebook.com/EOSGmbH

Explore the May 2019 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- HERMES AWARD 2025 – Jury nominates three tech innovations

- Vision Engineering’s EVO Cam HALO

- How to Reduce First Article Inspection Creation Time by 70% to 90% with DISCUS Software

- FANUC America launches new robot tutorial website for all

- Murata Machinery USA’s MT1065EX twin-spindle, CNC turning center

- #40 - Lunch & Learn with Fagor Automation

- Kistler offers service for piezoelectric force sensors and measuring chains

- Creaform’s Pro version of Scan-to-CAD Application Module