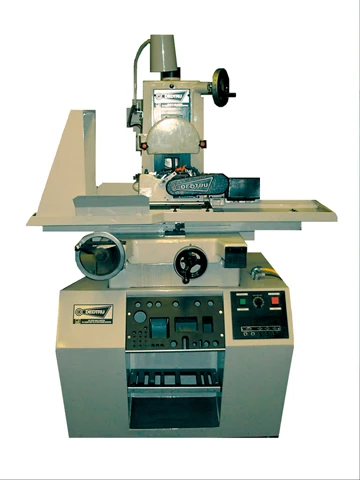

In recent years the demand for medical components has risen tremendously, particularly for devices like heart catheters which require the application of precision ground guide wires with concentricity tolerances of 10 millionths. The DedTru three-axis system provides both thru-feed and plunge centerless grinding for cylindrical parts ranging from 0.005-in. to 5-in. diameters with concentricity tolerances of 50 millionths.

Unfortunately, in today's manufacturing environment, much of the know-how and expertise for high-precision centerless grinding is disappearing. Even with sophisticated operator-friendly CNC software, it's still difficult to consistently machine to millionths. For this reason, Unison has established a new company named, Unison Precision Machining (UPM), specifically formed to serve precision component manufacturers. Staffed with highly trained centerless grinding technicians, this entity has the capability of producing short, medium and larger volume production runs.

For nearly 50 years Unison DedTru centerless grinding systems have been the mainstay for manufacturers requiring high-precision grinding. With over 10,000 installations worldwide, Unison machines have proven to be a standard for reliability and, according to the company, are considered the most cost-effective solution to both short lot and larger volume centerless grinding operations.

"Today, we're being approached by some of our capital equipment customers who need contract machining services for production requirements that they can't currently meet with their existing capacity," says Dave Swider, president of The New Unison Corp. "For this reason, we have established Unison Precision Machining to address those customer's needs and this company will only seek new business in areas which do not compete with Unison's existing equipment customer base."

"One of the areas that UPM is pursuing is the guide wire business for heart catheters. The high-precision concentric wires used in catheters are ideally suited for being ground on DedTru machines. The new company is equipped with Unison CNC grinding systems as well as DedTru grinding machines. UPM's grinding technicians have decades of experience with all types of production and prototype grinding work," explains Swider.

The New Unison Corporation designs and builds precision grinding machines, both manual and CNC. The company markets its products on a worldwide basis under the registered trademarks of TruFlute and DedTru with domestic sales locations in Pennsylvania, California, Illinois, Tennessee and Texas. International sales and support are provided in Australia, England, Italy, Israel, Thailand, China, India, Korea, Singapore, Taiwan and Japan. Unison equipment is used by some of the largest corporations in the world; Bausch & Lomb, Becton Dickinson, Bowing, Bosch, Boston Scientific, John Deere, Eveready Battery, Ford Motor Company, Guidant, Medtronics, Northrop Grumman, Rolls Royce, St. Gobain, St. Jude Medical Center and Textron, just to name a few.

New Unison Corp.

Ferndale, MI

newunison.com

Explore the June 2006 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Teleflex sells acute care and urology businesses for $2.03 billion

- HANNOVER MESSE: Where research and manufacturing meet

- What’s next for the design and manufacturing industry in 2026?

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Robot orders accelerate in Q3