Several years ago, Edward Evans fell seriously ill when an infection began eating away at his sternum – the bone at the center of the ribcage that protects the vital organs in the chest. Medication failed to eradicate the problem, so Evans had to undergo surgery to have the infected sternum and parts of his adjacent ribs removed.

At the time, it was impossible for the surgeons to do anything more than cover the resulting defect with Evans’ own muscle, because putting any foreign object into his chest when infection was rampant would almost certainly have resulted in that foreign material also becoming infected.

Evans recovered well from this surgery, but the absence of a solid sternum meant that his heart and lungs were extremely vulnerable, and his quality of life was limited. So doctors at Heartlands Hospital in Birmingham arranged for Evans to undergo another operation to have a new sternum implanted.

Normally in situations like this the implant would be made from a hand molded cement block wedged in a synthetic mesh. This is a tried and tested method, but surgeons have always been searching for a better, more modern alternative.

In Evans’ case thoracic surgeon Ehab Bishay was able to offer such an alternative – a custom sternum made from titanium and 3D printed on the other side of the world.

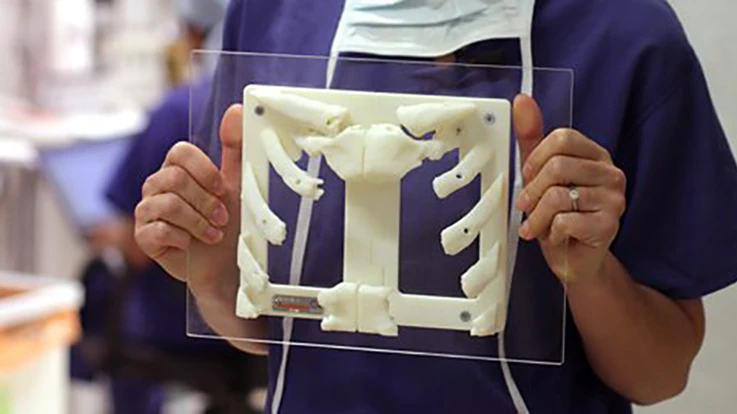

Titanium is a strong, lightweight, biologically compatible metal that becomes integrated, not rejected in human bodies. This, coupled with advances in 3D printing technology, allowed the creation of an implant that would precisely fill the defect in Evans’ chest.

Bishay sent CT scans of Evans’ chest to Anatomics Pty. Ltd. in Melbourne, Australia, who are world leaders in the design and manufacture of bespoke surgical implants.

Their designs were then sent to CSIRO where they were fed into a 3D printer. This printer has a chamber filled with powdered titanium, and the particles are fused together layer by layer by an electron beam.

The printed sternum was then returned to Anatomics for processing and cleaning and was coated in porous polyethylene – a substance manufactured to create a bone-like porous architecture and which also helps with tissue adhesion. Finally, the implant was sterilized and shipped to the UK.

Having made sure that Evans was now infection free, the team at Heartlands Hospital were able to operate.

The procedure began with plastic, reconstructive surgeon, Haitham Khalil, opening up Evans’ chest and removing the muscle flap that had been offering some limited protection to his organs. Then Bishay fitted the new sternum into place.

After a few minor adjustments, the perfect fit was achieved. As the team had hoped, the process was quicker and the fit better than it would have been with a traditional mesh and cement implant.

Although the procedure was a success, the team were keen to find out what impact this new kind of implant would have on Evans’ movement and breathing – would it match, or perhaps even improve on, the functionality of traditional implants?

To establish this, Dr. Nicola Oswald tested Evans’ breathing and chest function at various stages before and after the surgery. One of these tests involved the use of motion capture cameras which revealed exactly how his chest moved during breathing.

Before the procedure, these tests showed that when Evans was inhaling parts of his chest were moving inwards instead of outwards. But after the operation this had been corrected and his breathing and movement were in synchrony again.

3D printing offers great potential for the future of surgery – not only can parts be created that precisely fit a particular patient, but the materials used can minimize the risk of infection. For thoracic surgeons like Bishay, this technology is exciting because it could allow them to commission bigger and more complex implants to help patients like Evans, and to help patients who have lost bones due to chest wall tumors.

This procedure was only the first of its kind in the UK and the second in the world – so it’s going to be fascinating to see how this technology develops.

Latest from Today's Medical Developments

- Global Industrie - A meeting to understand, anticipate and contribute to the industry of tomorrow

- Wintriss’ Tracker Hardware Solution for ShopFloorConnect Production Tracking Software

- Protolabs expands end-to-end manufacturing capabilities

- Sunnen’s HTE-1600W Tube Hone

- Researchers invent soft, bioelectronic sensor implant

- HEULE’s DL2 tooling

- Application Park shows off diverse robotics applications

- Join our editors for a look at the manufacturing industry in 2025