Yong Chen

3D printing has the potential to revolutionize product design and manufacturing in a vast range of fields – from custom components for consumer products, to 3D printed dental products and bone and medical implants that could save lives. However, the process also creates a large amount of expensive and unsustainable waste and takes a long time, making it difficult for 3D printing to be implemented on a wide scale.

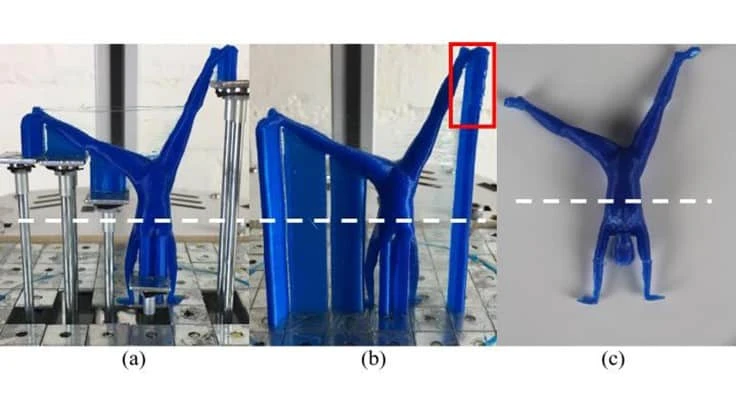

Each time a 3D printer produces custom objects, especially unusually shaped products, it also needs to print supports printed stands that balance the object as the printer creates layer by layer, helping maintain its shape integrity. However, these supports must be manually removed after printing, which requires finishing by hand and can result in shape inaccuracies or surface roughness. The materials the supports are made from often cannot be re-used, and so they're discarded, contributing to the growing problem of 3D printed waste material.

For the first time, researchers in USC Viterbi's Daniel J. Epstein Department of Industrial and Systems Engineering have created a low-cost reusable support method to reduce the need for 3D printers to print these wasteful supports, vastly improving cost-effectiveness and sustainability for 3D printing.

The work, led by Yong Chen, professor of industrial and systems engineering and PhD student Yang Xu, has been published in Additive Manufacturing.

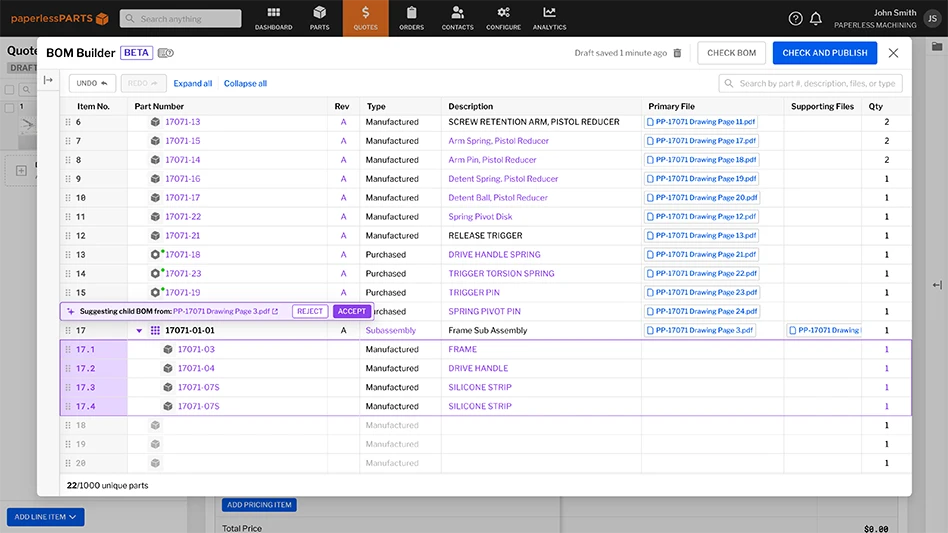

Traditional 3-D printing using the Fused Deposition Modeling (FDM) technique, prints layer-by-layer, directly onto a static metal surface. The new prototype instead uses a programmable, dynamically controlled surface made of moveable metal pins to replace the printed supports. The pins rise as the printer progressively builds the product. Chen says that testing of the new prototype has shown it saves around 35% in materials used to print objects.

"I work with biomedical doctors who 3D print using biomaterials to build tissue or organs," Chen says. "A lot of the material they use are very expensive we're talking small bottles that cost between $500 to $1,000 each."

"For standard FDM printers, the materials cost is something like $50 per kilogram, but for bioprinting, it's more like $50 per gram. So, if we can save 30% on material that would have gone into printing these supports, that is a huge cost saving for 3D printing for biomedical purposes," Chen says.

In addition to the environmental and cost impacts of material wastage, traditional 3D printing processes using supports is also time-consuming, Chen notes.

"When you're 3D printing complex shapes, half of the time you are building the parts that you need, the other half of the time you're building the supports. So, with this system, we're not building the supports. Therefore, in terms of printing time, we have a savings of about 40%."

Chen says that similar prototypes developed in the past relied on individual motors to raise each of the mechanical supports, resulting in highly energy-intensive products that were also much more expensive to purchase, and thus not cost-effective for 3D printers.

"So if you had 100 moving pins and the cost of every motor is around $10, the whole thing is $1,000, in addition to 25 control boards to control 100 different motors. The whole thing would cost well over $10,000."

The research team's new prototype works by running each of its individual supports from a single motor that moves a platform. The platform raises groups of metal pins at the same time, making it a cost-effective solution. Based on the product design, the program's software would tell the user where they need to add a series of metal tubes into the base of the platform. The position of these tubes would then determine which pins would raise to defined heights to best support the 3-D printed product, while also creating the least amount of wastage from printed supports. At the end of the process, the pins can be easily removed without damaging the product.

Chen explains the system could also be easily adapted for large scale manufacturing, such as in the automotive, aerospace and yacht industries.

"People are already building FDM printers for large size car and ship bodies, as well as for consumer products such as furniture. As you can imagine, their building times are really long – we're talking about a whole day," Chen says. "So, if you can save half of that, your manufacturing time could be reduced to half a day. Using our approach could bring a lot of benefits for this type of 3D printing."

Chen says the team had also recently applied for a patent for the new technology. The research was co-authored by Ziqi Wang, previously a visiting student at USC, from the School of Computer and Communication Sciences, EPFL Switzerland, and Siyu Gong from USC Viterbi.

Latest from Today's Medical Developments

- North America's supply chains face sharp decline due to tariffs

- Experience precision: GF Machining Solutions' CUT F Series wire EDM

- Mastering high-temp alloys with Kennametal Inc.

- Integer expands operations in Salem, creating 83 jobs

- Siemens unveils new Teamcenter X: Revolutionizing SaaS PLM for all manufacturers

- 3 Questions with an Expert with Allied Machine & Engineering

- Supply Chain Power – A strategic program for executives

- Sunnen Products' PGE-6000 gage