Sustainability is increasing in importance in all international markets. The pharmaceutical industry is no exception, considering its environmentally taxing processes involving solvents, reagents, water, and other agents. Along with sterility assurance, process validation, and regulatory compliance, sustainability is becoming a more high-profile component in pharmaceutical processing, and considered a critical factor in the design of healthcare equipment, products, and packaging.

Sustainability is increasing in importance in all international markets. The pharmaceutical industry is no exception, considering its environmentally taxing processes involving solvents, reagents, water, and other agents. Along with sterility assurance, process validation, and regulatory compliance, sustainability is becoming a more high-profile component in pharmaceutical processing, and considered a critical factor in the design of healthcare equipment, products, and packaging.

The concept of sustainability has been a topic of interest for many years, and has been more formally discussed and considered since the late 1980s.

Current international focus has led to the development of regulatory guidance in many of the world’s markets.

The United States Environmental Protection Agency (EPA) has posted the following definition of sustainability on its website www.epa.gov/sustainability/basicinfo.htm: “Sustainability is based on a simple principle: Everything that we need for our survival and well-being depends, either directly or indirectly, on our natural environment. Sustainability creates and maintains the conditions under which humans and nature can exist in productive harmony, which permits fulfilling the social, economic, and other requirements of present and future generations.”

.gif) BFS produced vials and bottles eliminate BFS produced vials and bottles eliminatethe need for secondary packaging. |

The major emphasis with sustainable procedures in pharmaceutical manufacturing is toward reducing environmental impact, by decreasing consumption of raw materials and energy usage in manufacturing and packaging processes, and by using more recycled materials.

There are many processes in pharmaceutical manufacturing that can be addressed to improve sustainability, and at the same time reduce operating costs. One of the most critically important objectives in achieving sustainability is reducing process energy consumption. Implementing energy-efficient practices and technologies should be a senior priority at the component, process, and system levels.

Energy monitoring systems and process control systems are key tools that play an important role in energy management to reduce energy use. Such systems include metering, monitoring, and system controls, such as integrated programmable logic controllers (PLCs). These minimize the time required to perform complex tasks and increase efficiency in process operations. Such automated process technologies that reduce energy consumption can also improve product quality and consistency, and increase production throughput.

Embracing process sustainability and energy efficiency in the pharmaceutical industry is the aseptic blow-fill-seal (B/F/S) system for packaging pharmaceutical liquids, which has made significant strides in achieving sustainability objectives.

Aseptic B/F/S technology integrates the three-step process of blow molding, sterile filling, and hermetic sealing in one continuous, highly automated operation. Unique to aseptic B/F/S systems compared to traditional aseptic processing is their capability for rapid container closure and minimized aseptic interventions.

B/F/S is a self-contained process, where the raw materials are virtually completely recyclable. The consolidation of process steps, through use of B/F/S, results in a significant reduction in the carbon footprint for the entire liquid filling and packaging production process. The products produced by aseptic B/F/S present a strong platform for sustainability from a variety of perspectives.

LEFT: B/F/S enables the system integration of unique packaging features like top geometrics and engraving that minimize processing steps. RIGHT: The use of Aseptic B/F/S is to produce containers for injectables, ophthalmics, biologicals and vaccines, which are generally considered inert by the FDA. LEFT: B/F/S enables the system integration of unique packaging features like top geometrics and engraving that minimize processing steps. RIGHT: The use of Aseptic B/F/S is to produce containers for injectables, ophthalmics, biologicals and vaccines, which are generally considered inert by the FDA. |

Assessing Sustainability

Pharmaceutical manufacturers possess a wide degree of latitude in selecting and implementing systems for achieving environmental sustainability and energy efficiency. However, foremost is the necessity to have a structured methodology that clearly delineates overall sustainability initiatives and process improvements.

Two basic types of structured programs are available to companies that manufacture pharmaceutical products:

a) Programs that address multiple aspects of sustainability, such as LEED (Leadership in Energy and Environmental Design), which provides a step-by-step process to achieve certification and recognition of having reached specific levels of compliance, and

b) Programs that provide assessment and planning tools for reducing energy consumption and plant process costs.

Both types of programs use a set of guidelines for evaluating the environmental impact involved when manufacturing, packaging, and distributing a product.

LEED is a certification program developed by the U.S. Green Building Council (USGBC), applicable to any building type and any building life cycle phase. It provides a framework for identifying and implementing practical and measurable green building design, construction, operations, and maintenance solutions.

LEED promotes a whole-building approach to sustainability by recognizing performance in key areas, such as sustainable sites, water efficiency, energy, materials, indoor environmental quality, location, and building design. The program’s internationally recognized green building certification system provides third-party verification that the design and build of a building utilized strategies aimed at improving performance across these metrics.

Although LEED certification does cover the actual physical facility and its habitable spaces, it does not provide benchmarks for manufacturing and packaging processes within the plant. For pharmaceutical manufacturers, whose plant operations represent a significant energy draw, which sizably impacts their sustainability, a more process-oriented sustainability program would be needed to accurately assess environmental impact.

Similar to LEED is Green Globes, operated by the Green Building Initiative in the United States. Green Globes is a building environmental design and management tool used throughout the United States and Canada. It encompasses both sustainability and energy management criteria, such as integration of energy efficient systems, renewable energy, cogeneration, and on-site wastewater treatment systems, in addition to sustainable environmental practices, such as sustainable site development and indoor air quality.

Green Globes delivers an online assessment protocol, rating system and guidance for green building design, operation, and management for light industrial applications like pharmaceutical manufacturing. Nevertheless, the program does not govern industrial process, which omits the significant energy savings that are achievable when considering these processes.

The Building Research Establishment’s Environmental Assessment Method (BREEAM) is a leading European environmental program for building practices in sustainable design. The program can assess light industrial operations like pharmaceutical plants, such as manufacturing, assembly, and packaging facilities both at the design stage and after construction. Factors considered are energy management, wastewater, land use, pollution, building materials, and other sustainability factors. Credits are awarded in each of the above areas in accordance with performance. A set of environmental weightings then enables the credits to be added together, producing a single overall score.

However, like LEED and Green Globes, process assessment is not in this program, which means it is an incomplete assessment system for the sustainability requirements of pharmaceutical manufacturers.

A program that does address process in pharmaceutical plants is Energy Star, sponsored by the U.S. Department of Energy (DOE), and administered through the Environmental Protection Agency. Its program provides tools and resources to help improve the energy efficiency of manufacturing and industrial facilities, including plant manufacturing and packaging processes.

Energy Star supplies an energy guide specifically for the pharmaceutical industry, which helps manufacturers evaluate potential energy improvement options, and develop action plans and checklists for the energy program. A major benefit is that it allows industrial companies to measure the energy use of their facility, and to benchmark it with other, similar facilities. Companies input key plant operating data into an energy performance indicator to receive an efficiency score. It is a critical management tool for evaluating how efficiently a plant is using energy compared to other companies in their industry.

Also supporting energy efficiency in pharmaceutical processes is the DOE’s Industrial Technologies Program (ITP), run by the Office of Energy Efficiency and Renewable Energy. This program addresses process functions in manufacturing plants that use steam, compressed air, process heat, electric, and other systems that could potentially be a source of wasted energy. It focuses on reducing energy use by integrating new technologies in industrial controls, automation and robotics, and provides concrete guidelines to achieve energy sustainability.

The ITP regularly conducts and makes available analytic studies to identify energy-reduction opportunities within industrial processes, making these results available to participant manufacturers. Application of the ITP program has resulted in significant energy savings, waste reduction, increased productivity, lowered emissions, and improved product quality for U.S. industrial manufacturers.

Choosing the right program is critical to how quickly a pharmaceutical manufacturer can achieve its energy efficiency and sustainability goals. A company’s best strategy may be to implement more than one of these programs. A plant may decide to run with Energy Star or ITP for its process energy improvements, while simultaneously going with LEED or Green Globes for its other sustainability initiatives. Alternatively, a manufacturer may choose to integrate state energy efficiency programs with LEED, Green Globes, or ITP to capitalize on state energy credits or low interest loans and grants that the states may offer for energy-efficient solutions or equipment.

LEFT: Illustration of an advanced aseptic B/F/S system. CENTER: B/F/S utilizes plastic resins that are recyclable. RIGHT: The latest generation B/F/S machines, such as this ASEP-TECH shown above to the right, support sustainability. LEFT: Illustration of an advanced aseptic B/F/S system. CENTER: B/F/S utilizes plastic resins that are recyclable. RIGHT: The latest generation B/F/S machines, such as this ASEP-TECH shown above to the right, support sustainability. |

Life Cycle Analysis and B/F/S

The environmental performance of products and processes in all industrial sectors, including pharmaceutical processing, has become a key issue. To better determine how sustainable products and processes really are, life cycle analysis (LCA) has emerged as a recognized instrument to assess the ecological burdens and impacts connected with them.

A life cycle analysis is unique as a technique because it assesses environmental impacts associated with all stages of a product’s life from cradle to grave. This includes raw material extraction through materials processing, manufacture, distribution, use, repair and maintenance, and disposal or recycling. LCA can be used to find the most ecological way to improve product manufacturing, and can be a useful decision-making tool for new products and process development. It is also useful as a guide for the optimization of energy and raw material consumption.

Cradle-to-grave life cycle analysis, through mathematical modeling, makes it possible to determine and manipulate key metrics to provide a weighted average on total sustainability. Values for energy and resource consumption, the extraction and processing of the raw materials, the pollution produced, recyclability, and the effects of associated transportation on the environment are applied in a numerical equation.

The weighted average then gives a clear evaluation of a sustainable solution for the product and manufacturing/packaging process under examination.

The LCA process is a systematic, phased approach and consists of four components:

- Establishing the context and parameters of the analysis

- An inventory, consisting of an identification and quantification of energy, water, and materials usage and environmental releases

- An impact assessment of these inventory factors, and the potential human and ecological effects, and

- The different environmental impacts are weighted relative to each other, and then summed to get a single number representing the total environmental impact.

An LCA allows a decision maker to study an entire product system and its processes, thereby avoiding the sub-optimization that could result if only a single process were the focus of the study.

In a comparison of different liquid pharmaceutical containers, for example, to determine which container had the lowest releases to the environment and least affected the supply of natural resources, an LCA would quantify the raw materials used and the environmental loadings (including energy consumption) from the manufacturing and packaging processes used to produce each container. It would also view comparative ecological impacts from distribution, consumption and disposal or reuse of each container.

When selecting between two packaging processes, for example, it may appear that one is better for the environment because it generates less chemical emissions at the point of packaging. However, after performing an LCA, it could be determined that the preferred process actually creates larger cradle-to-grave environmental impacts when measured across its influence on air, water, and land. The packaging process may use a film that is difficult or impossible to recycle. Therefore, the unselected process may now be viewed as producing less cradle-to-grave environmental harm or impact than the initial preferred technology.

From a life cycle analysis perspective, aseptic B/F/S machines that provide packaging of pharmaceutical liquids present much more streamlined and sustainable systems for production of sterile products, compared to traditional aseptic processing in a number of critical aspects.

Energy Management – The most advanced aseptic B/F/S systems are quite automated, compared to traditional aseptic processing. Designs of these B/F/S machines are to require minimum human access while operating in Class-100 environments.

Various in-process control parameters, using the latest generation of fully system-integrated PLCs, control and monitor container weight, fill weight, wall thickness, isolation of visual defects, and other factors facilitating optimized system function.

These B/F/S machines allow very efficient processing speed and short machine cycle times. Aside from the obvious improvement in throughput volume, they provide more efficient energy usage.

According to the DOE’s Energy Star program, implementation of monitoring and control systems, such as PLCs and servo-drives, present well-documented opportunities for energy savings.

Recyclable Plastic Containers – Aseptic B/F/S systems incorporate the use of recyclable plastic resins, as differentiated from glass containers used in traditional aseptic processing. Generally considered inert by the FDA are low-density polyethylene, high-density polyethylene, and polypropylene, all utilized for the production of aseptic containers for injectables, ophthalmics, biological, and vaccines. These inert materials do not contain additives, have low water vapor permeability, and are easy and safe to handle in critical care environments such as hospitals.

These resins used in B/F/S processes are recyclable. Regulatory requirements permit reuse of the resin up to three times before it must be discarded. As much as 50% of the resin used in the B/F/S process can be reground and directly used again within the process when mixed with virgin material.

The remainder of the waste can be captured and used for other applications.

The entire production and recycle processes can be maintained on-site with minimal need for off-site disposal of waste material.

Reduced Manual Interventions – Waste reduction should be viewed as an important objective in a sustainability program. In aseptic packaging of pharmaceutical liquids, waste can manifest itself in compromised quality, labor-intensive processes and reduced efficiency.

Traditional aseptic procedures for packaging pharmaceutical liquids involves multiple steps in the handling and manipulation of the material, containers and sterilization filling processes with human intervention, and therefore have a higher potential for contamination during processing. Additional steps for conventional aseptic processing include receiving, inspection, and warehousing of incoming containers, washing and sterilizing of containers, separate processing steps and equipment for filling and sealing, and end processing handling.

The FDA’s 2004 Guidance for Industry Sterile Drug Products Produced by Aseptic Processing states that the design of equipment used in aseptic processing should limit the number and complexity of aseptic interventions by personnel. Both personnel and material flow should be optimized to prevent unnecessary activities that could increase the potential for introducing contaminants to exposed product, container-closures, or the surrounding environment.

The latest generations of B/F/S machines, as exemplified in the ASEP-TECHR B/F/S system from Weiler Engineering, are highly automated, thereby severely reducing manual interventions. One unit operation achieves the forming, filling, and sealing steps, with the cycle completing within seconds. Such automation eliminates unneeded labor and reduces the risk to lessened product integrity.

Elimination of Secondary Packaging – B/F/S produced vials and bottles, by virtue of their opening features and simplified designs, such as twist-off tops, eliminate the need for secondary packaging. Labeling is not needed, since the molds can be engraved with product information. This avoids an additional process step, and eliminates the potential for additional waste generation.

Integrated Packaging of Inserts – B/F/S allows pre-molded, pre-sterilized components, called inserts, to be integrated into the basic container. These inserts, including items such as rubber and silicone stoppers, and tip-and-cap dropper units for eye drop containers used to deliver a calibrated drop, attach to the container after the blowing and filling process. These improvements streamline the packaging process.

Changeover Flexibility – When there is an interruption to aseptic throughput, or it is not running because of downtime, the entire process line is impacted, which represents a significant production loss to the manufacturer. Configuration of many B/F/S machines is to produce more than one bottle shape or format.

This makes it easy to change from one container size to another. A B/F/S machine might produce a family of 2mL, 3mL, and 5ml, then switch to a family of 5mL, 10mL, and 15ml, or to one of 10mL, 15mL, and 20ml, moving from one to the other with relative ease of machine set-up. B/F/S systems approach 99% uptime efficiency, significantly higher than traditional aseptic processing, which is plagued with slow-downs and process interruptions in part because of required manual interventions.

Embracing Sustainability

The B/F/S system improves product integrity and better ensures patient safety over traditional aseptic processing procedures. As a result, the FDA and the United States Pharmacopoeia now characterize modern B/F/S technology as an advanced aseptic process, indicating its use as a preferred technology over other aseptic systems, and a better solution for the sterile, aseptic processing of pharmaceutical liquids. Waste reduction, resource and energy management, improved process controls and throughput efficiency are key factors that have influenced the acceptance of aseptic B/F/S. These are critical functions for achieving sustainable practices in the packaging of aseptic pharmaceutical liquids. They save energy, increase productivity, and reduce environmental impacts.

Advanced aseptic B/F/S technology has emerged as an innovation in green technology within the pharmaceutical packaging sector. As government agencies and pharmaceutical manufacturers steadily, but surely, embrace the sustainability initiative, aseptic B/F/S technology will continue to occupy a prominent position in the evolution of Green Processing.

Weiler Engineering Inc.

Elgin, IL

www.weilerengineering.com

Explore the October 2012 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Betacom, Siemens launch 5G network platform to accelerate manufacturing innovation

- Starrett’s AVR400 CNC vision system

- US cutting tools orders decreased 2% from November 2024

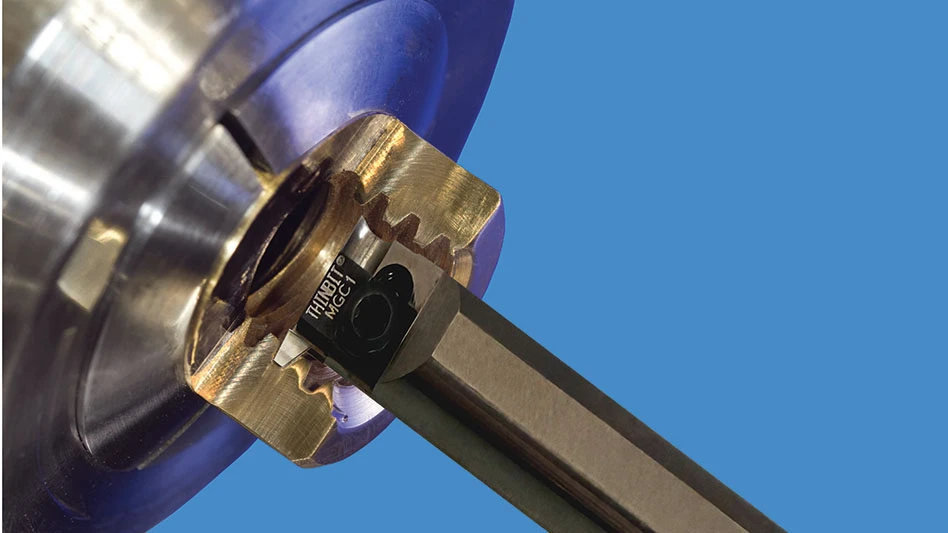

- SMW Autoblok's Manual Jack connection kit

- MedTech Innovator welcomes five new industry partners

- First Article Inspection for quality control

- The manufacturing resurgence is here – are you ready?

- Workholding solutions for your business