MSC’s customizable CAP vending equipment effectively dispenses tools in exact quantities, establishes total user accountability, eliminates stock outages, and tracks tooling spends on various jobs at EPTAM. MSC’s customizable CAP vending equipment effectively dispenses tools in exact quantities, establishes total user accountability, eliminates stock outages, and tracks tooling spends on various jobs at EPTAM. |

Thanks to tiny micro-needles, eye doctors may soon have a better way to treat diseases such as macular degeneration that affect tissues in the back of the eye. That could be important as the population ages and develops more eye-related illnesses – and as pharmaceutical companies develop new drugs administered through injections into the eye with a hypodermic needle.

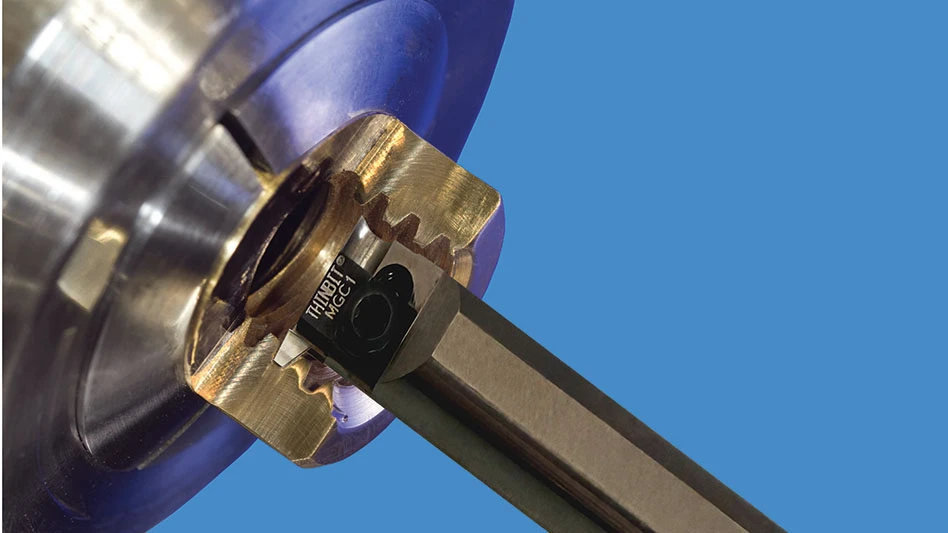

Modern machine tools with advanced cutters and inserts have made it possible for manufacturers to be more productive and competitive than ever before. However, as shops secure more and more work, effective tool management and supply chain optimization is crucial to reducing costs and increasing overall productivity.

Many purchasing agents are unable to tell what tools currently exist inside their shop, how much disposable tooling their company uses, or even what type of insert they need to order at a given time. In addition, if they do have this information, it is commonly stored on paper and filed away or saved in a simple Excel spreadsheet – both of which are difficult to maintain.

Companies using such methods, or nothing at all, to manage hundreds, even thousands of tools, cutters, and inserts should consider an advanced inventory management system as a means of gaining a competitive advantage and driving costs out of manufacturing applications.

EPTAM Plastics Inc., a leading manufacturer of precision-machined plastic components based in Northfield, NH, uses MSC Industrial Supply Co.’s customizable CAP vending equipment. Implementation success has been in effectively dispensing tools in exact quantities, establishing total user accountability, eliminating stock outages to avoid machine downtimes, and tracking tooling spends on various jobs – all for the sake of streamlining the company’s supply chain and achieving quantified savings.

An EPTAM employee swipes his employee An EPTAM employee swipes his employeebadge in order to access the shop’s MSC vending system. |

According to Sandy Bedford, tooling and hardware coordinator for EPTAM, the company operates from a state-of-the-art 60,000ft2 manufacturing facility, serving several industries, including medical, energy, and military aerospace. In fact, EPTAM devotes more than 11,000ft2 alone to the exclusive machining of medical grade polymers. Because this area needs to remain clean and uncluttered – as the machine operators here use 105 different tools, including expensive diamond-coated custom tooling – EPTAM relies on MSC’S vending system in this space to provide accurate inventory control, 24/7 secure access, and measurable operating efficiencies.

“I like the fact that the MSC tool crib allows me to effectively monitor tool usage,” Bedford says. “If an employee dispenses a tool that can typically machine up to 150 parts and he or she returns within the hour to check out a second tool, I know something is wrong. If it turns out to be a machining issue, I can nip the problem in the bud before we go through 10 tools and waste money.”

Bedford goes on to explain that MSC’S vending system has, “definitely increased my tool purchasing productivity by at least 30%. [In addition,] my daily reports let me know what tooling is running low and I can opt for automatic replenishment with next day delivery, which is great because it cuts down on the time I used to spend requisitioning tools.”

Various drawer sizes available with the MSC vending system at EPTAM allow the shop to accommodate different-sized tooling and use a kitting function that dispenses multiple tools, in the proper quantities with one command, without the need for pre-building kits. Various drawer sizes available with the MSC vending system at EPTAM allow the shop to accommodate different-sized tooling and use a kitting function that dispenses multiple tools, in the proper quantities with one command, without the need for pre-building kits. |

Vending systems from MSC are modular and expandable, allowing them to adapt, easily, to the constant changes within the manufacturing industry. The system’s multi-access drawer modules require no repackaging and do not drop items. Various drawer sizes are available to accommodate different-sized tooling. Furthermore, they have a kitting function that dispenses multiple tools- in the proper quantities, with one command, and without the need for pre-building kits.

Advanced software enables MSC’s vending systems to integrate, electronically, with EPTAM’s business network for complete worry-free inventory management. It offers standard reporting as well as more than 35 highly configurable reports in real time to any authorized EPTAM employee on the network. The software will also automatically send employees reports in a highly usable format.

Because every company is different and no one vending solution fits all, MSC offers a free assessment to anyone interested in a customizable vending solution. A supply chain expert from MSC will visit a company to analyze its existing environment and identify the most important business challenges. MSC supply chain experts then make recommendations as to what the best inventory solution will be for a company’s exact needs. If the company decides to move forward, MSC then works closely with the company on installation and training.

According to Bedford, MSC’s vending system is so user friendly that it essentially takes only about four minutes to train someone on how to use it. She goes on to say that if she ever needs help with her vending system, the MSC staff, trained in helping her from a remote location, means she never has to wait more than 10 minutes to get an answer to her question. If something needs addressed with the vending system that she cannot handle herself, which is very rare, Bedford says her MSC representative comes out and addresses it that same day.

EPTAM follows a similar approach when serving its customers. “We have a great working relationship with our clients,” Bedford notes. “EPTAM believes in an open line of communication so if a customer issue arises, we can respond on the fly. Plus, we are not afraid to take emergency jobs that are going to get our customers out of a bind.”

The company uses a collaborative engineering approach to meet, effectively, each of its customer’s needs. EPTAM’s sales and process engineers work closely with customers on manufacturing and quality requirements, ensuring they meet product specifications and schedules for launch and delivery.

Bedford notes that MSC is part of the reason EPTAM is able to address its customers so quickly, not only by way of the vending system but also through MSC’s vendor managed inventory, or VMI, service. EPTAM orders a number of supplies from MSC, including WD-40, counter sinks, earplugs, and safety glasses, and every Monday someone from MSC comes and checks the company’s stock levels. Later in the day, Bedford receives a report via email of what supplies are low as well as a replenishment quote. Once she selects what she wants to reorder, her MSC representative returns to EPTAM two days later with her supplies.

EPTAM understands that having real-time tooling answers and being able to track tool usage over time is essential in maintaining the on-time delivery of its precision-machined plastic components to a wide variety of customers across the United States as well as Asia, Switzerland, and Germany. It is so crucial to the company that recently, a second MSC vending system went into its operations.

MSC Industrial Supply Co.

Melville, NY

www.mscdirect.com

EPTAM Plastics Inc.

Northfield, NH

www.eptam.com

Explore the October 2012 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Betacom, Siemens launch 5G network platform to accelerate manufacturing innovation

- Starrett’s AVR400 CNC vision system

- US cutting tools orders decreased 2% from November 2024

- SMW Autoblok's Manual Jack connection kit

- MedTech Innovator welcomes five new industry partners

- First Article Inspection for quality control

- The manufacturing resurgence is here – are you ready?

- Workholding solutions for your business