Offering a broad range of products and services related to the manufacture of thermoplastic injection molded components and assemblies, the staff capabilities at Injectronics includes product development, injection molding, thermoforming, high-speed automated inspection, packaging systems, and contract assembly of medical devices. Founded in 1942, Injectronics’ management focuses on developing and acquiring leading-edge manufacturing techniques and technologies, quality and delivery systems, and business management methods. With continual, heavy investment in employee training for optimum proficiency in the use of these resources at all levels, officials from Injectronics promote the company as a world-class quality solutions business partner.

The staff at Injectronics understands the importance of rapid response to market-driven industry changes. Because of this, management continues to investigate new molding technologies as well as other manufacturing methods to add value for the customer and reduce the need for multiple suppliers.

Considered an engineering-based company, the employees at Injectronics use a program management approach to product and process development, allowing customers to access all company support functions through a single contact – their Injectronics program manager – who takes the lead responsibility for all aspect of the new product introduction. These degreed plastics engineers – the program managers – lead interdisciplinary teams on all aspects of the production process.

|

Name: Location: Website: Beginnings: SPECS/CERTS: Motto: |

Injection Molding

- ISO Class 8 (Class 100,000) certified cleanroom molding and assembly

- Conventional molding

- Overmolding

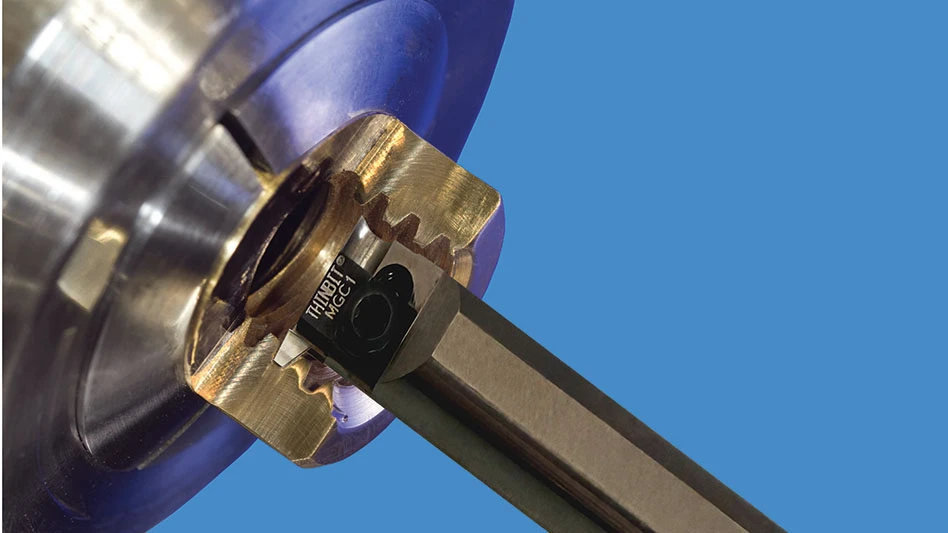

- Insert molding

- In-mold decorating

- Vertical injection molding

Thermoforming

- ISO Class 8 certified cleanroom

- Equipment uses 6-axis articulating robots

- Closed loop material melt temperature controls

Robotics and Automation

- Automated production workcells

- Automatic packaging and inspections systems

- Servo robotic part removal

- Value added operations

Contract Manufacturing & Assembly

- Complex electro-mechanical assembly

- Integration of electronic flex circuits

- Modules consisting of plastic and non-plastic

- Water and gas pressurized leak testing

- Mechanical assembly electronics, water resistance data storage containers

Explore the October 2012 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Betacom, Siemens launch 5G network platform to accelerate manufacturing innovation

- Starrett’s AVR400 CNC vision system

- US cutting tools orders decreased 2% from November 2024

- SMW Autoblok's Manual Jack connection kit

- MedTech Innovator welcomes five new industry partners

- First Article Inspection for quality control

- The manufacturing resurgence is here – are you ready?

- Workholding solutions for your business

.gif)