![]() Enabling Miniaturized Implantable Medical Devices

Enabling Miniaturized Implantable Medical Devices

A new die packaging technology passes an internal qualification regime typical for active implantable medical devices consisting of thermal and mechanical stressing to MIL-STD-883 test standards. The die packaging technology targets implantable medical devices such as pacemakers and cardiac defibrillators. The technology can also be used in wearable devices, such as hearing aids and intelligent patches, as well as nerve stimulators and drug delivery products.

Microsemi’s breakthrough packaging technology delivers a footprint reduction of approximately 75% compared to the company’s currently available implantable radio modules. Device miniaturization allows physicians to use less invasive procedures, enabling faster recovery times and improvements in patient comfort while concurrently lowering health care costs. Smaller, lighter weight wireless medical devices also afford patients greater mobility. https://www.microsemi.com/

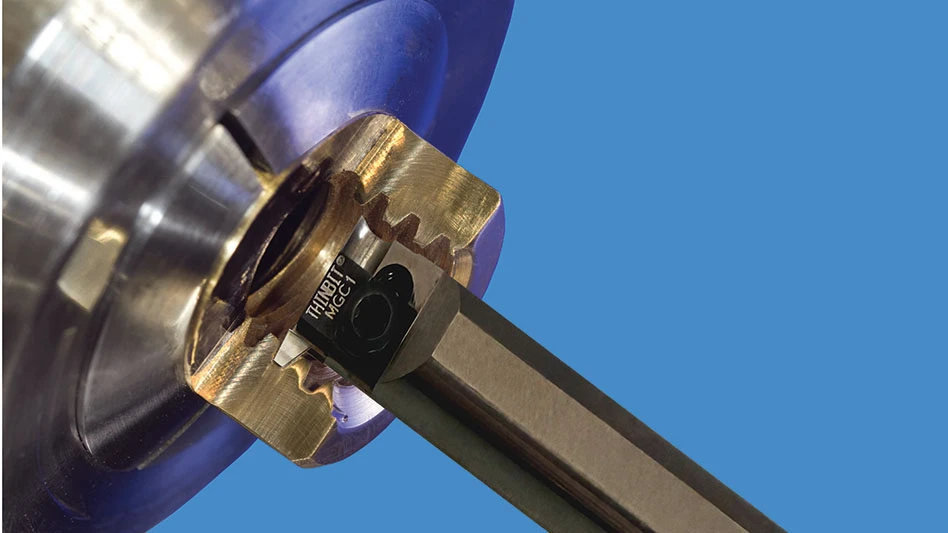

Grinding App Available for Speeds, Calculations, Product Selection, More

Grinding App Available for Speeds, Calculations, Product Selection, More

The Norton Abrasives Grinding App, from Saint-Gobain Abrasives, includes a wheel speed conversion calculator, a coolant and dressing parameter calculator for abrasives applications, a right angle grinding product selector, as well as a distributor locator. A link to Norton’s abrasives connection and website to find and order product, and check orders and inventory, is available, in addition to a convenient button to contact a representative. The Norton Grinding App is available for IOS and Android operating systems on mobile devices. To download the App, go to www.nortonindustrial.com/Grinding CalculationApp.aspx.

Pre-Bionic Eye Delivering Sight

Pre-Bionic Eye Delivering Sight

Bionic Vision Australia researchers have successfully performed the first implantation of an early prototype bionic eye with 24 electrodes.

Dianne Ashworth has profound vision loss due to retinitis pigmentosa, an inherited condition. After receiving a pre-bionic eye implant, as researches switched it on while at the Bionic Institute, Ashworth exclaims she could see a little flash, and that after subsequent stimulation to the device, different shapes appeared in front of her eye.

The bionic eye is a retinal prosthesis designed to restore the sense of vision to people who are blind due to degenerative retinal conditions. This technology uses a retinal implant and a digital camera mounted on a pair of glasses. The camera captures images, processes them, and sends data to the implant. The implant contains a number of electrodes, that stimulate the remaining cells of the retina to elicit the perception of vision. https://bionicvis.com/

Growth, Expansion

Last month a $19M Cook Medical production plant opened in Canton, IL, adding 60 high-skill jobs to the local economy. This facility joins an existing Cook factory in Canton that opened in 2010. The new facility will be the home for manufacturing of polytetrafluoroethylene (PTFE) tubing, which has uses in a broad variety of different medical devices manufactured by Cook employees. http://www.cookmedical.com

20 Years in U.S.

20 Years in U.S.

The staff at the Morrisville, NC, Schunk facility has been manufacturing toolholding products and providing sales and support to local customers for the past 20 years – ever since the U.S. facility opened in 1992. This has led to unparalleled success for North America, spurring the development of two more entities, Schunk Canada and Schunk Mexico, in 2006. http://www.schunk.com

Explore the October 2012 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Betacom, Siemens launch 5G network platform to accelerate manufacturing innovation

- Starrett’s AVR400 CNC vision system

- US cutting tools orders decreased 2% from November 2024

- SMW Autoblok's Manual Jack connection kit

- MedTech Innovator welcomes five new industry partners

- First Article Inspection for quality control

- The manufacturing resurgence is here – are you ready?

- Workholding solutions for your business