A team of researchers, led by the Science and Technology Facilities Council (STFC), have developed a high technology process designed to coat surgical implants with fibers that, for the first time, will encourage the implant to "bond" with living bone in order to last the lifetime of the patient. This is a brand new process that could revolutionize the reliability and durability of surgical implants such as hip and knee replacements.

This unique surface engineering process is being developed at the Micro-Nano Technology Centre (MNTC) at STFC. In collaboration with The Electrospinning Company Ltd. (TECL) and Anglia Ruskin University, the concept will be taken forward under the guidance of a medical futures team, and eventually exclusively licensed to TECL, a spinout company of STFC.

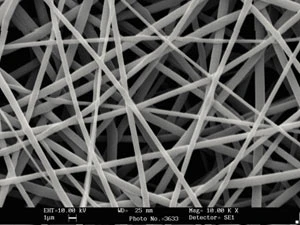

This advanced nanotechnology technique builds on an existing technique known as electrospinning, and will utilize a vastly superior electrospinning source to create unique fibrous materials.

Electrospinning is a process that uses an electrical charge to turn polymers into extremely thin fibers that are "spun" to form a mat of fine fibers. It is seen as a platform technology for the medical sector with a wide range of applications including tissue regeneration and drug delivery. MNTC has developed systems to increase the production rate of nanofibers, which has previously prevented this technology from being adopted by industry.

In this case, nanosized hair-like structures, a thousand times thinner than the width of a human hair, are electrospun at MNTC and added to the surface of an orthopaedic implant to create a "living interface" between the artificial implants and living bone. Not only does this improve the performance of the implants, it also significantly increases their durability to last the lifetime of the patient. Any stress on the implant is relieved, making it more reliable and durable. Additionally, it is also possible to add a unique biological coating that can facilitate growth and improve the bonding of healthy tissue to the implant, primarily benefitting patients with osteoarthritis in the aging population and sports injuries in the younger population.

This process will be transferred to UK industry and TECL will provide access to state-of-the-art electrospinning systems.

TECL has spun out from STFC to provide open access to electrospinning equipments and expert i s e to organizations that would like to explore the technique's potential. The main benefit is that this can be done without commercial companies committing to capital investment or developing inhouse expertise until the potential value of electrospinning to the organization is fully understood. TECL was founded by CLIK, the wholly-owned technology exploitation company of STFC. TECL's specialized facilities are designed to extend current electrospinning capabilities so that nanofibers can be reproduced in volume.

Mansel Williams, chief executive of TECL says: "Ten percent of patients receiving surgical implants go on to develop infection and loosening of their implants, costing the UK at least £14 million ($20.5 million) every year, £224 million globally ($327 million). We want to eliminate this by creating the ideal implant surface matched to the individual patient, benefitting both the patient and the economy."

Science and Technology

Facilities Council

Didcot, United Kingdom

stfc.ac.uk

Explore the May 2009 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Robot orders accelerate in Q3

- Pro Shrink TubeChiller makes shrink-fit tool holding safer, easier

- Revolutionizing biocompatibility: The role of amnion in next-generation medical devices

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.